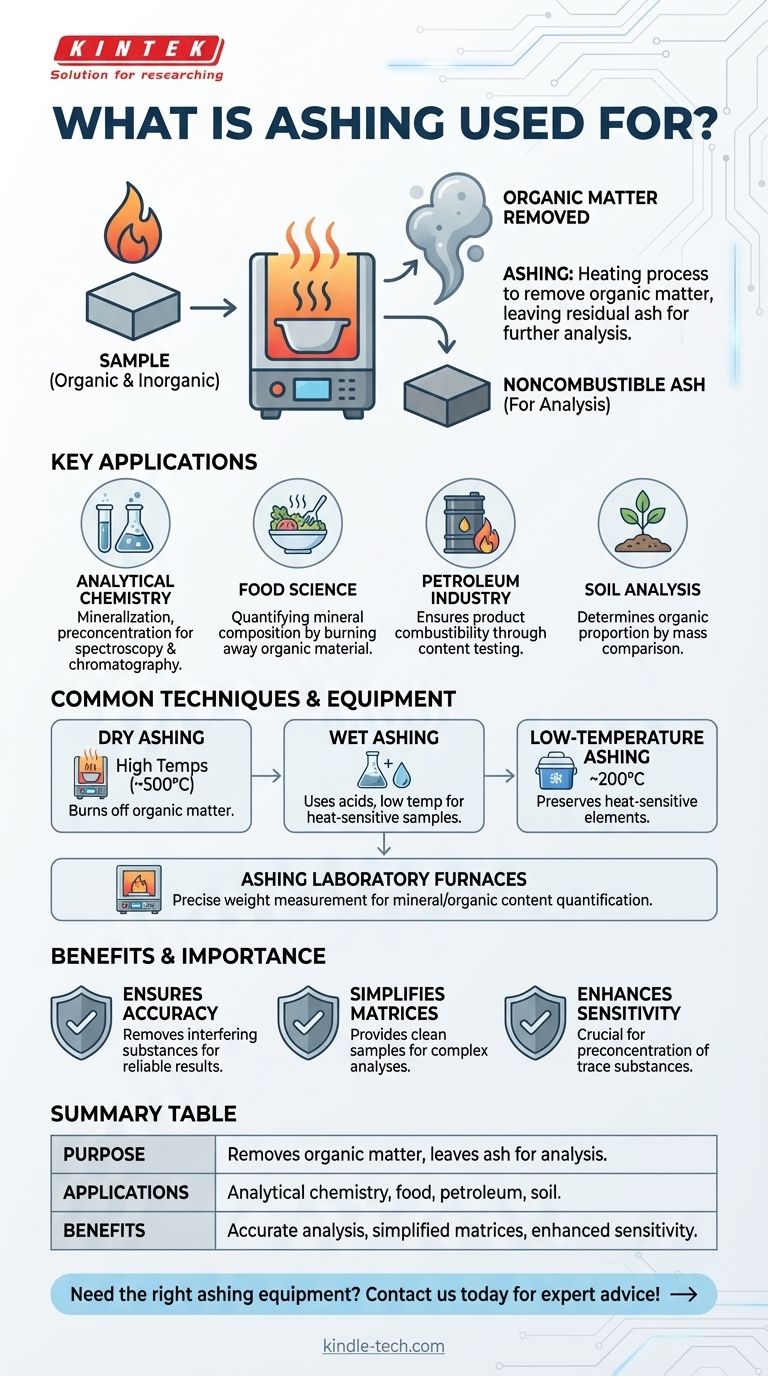

Озоление — это критически важный процесс, используемый в различных отраслях промышленности и научных областях для удаления органических веществ и других мешающих компонентов из образцов, оставляя несгораемую золу для дальнейшего анализа. Он широко применяется в аналитической химии, пищевой промышленности, испытаниях нефтепродуктов и анализе почвы. В зависимости от типа образца и аналитических требований используются такие методы, как сухое озоление, мокрое озоление и низкотемпературное озоление. Озоление помогает количественно определить минеральный состав, обеспечить горючесть продукта и подготовить образцы для таких методов, как спектроскопия и хроматография. Оно также необходимо для предварительного концентрирования следовых веществ и определения органических пропорций в таких материалах, как почва.

Объяснение ключевых моментов:

-

Определение и назначение озоления

- Озоление — это процесс, который включает нагревание образца для удаления органических веществ и других мешающих компонентов матрицы, оставляя несгораемую золу.

- В основном он используется для подготовки образцов к точному анализу путем устранения компонентов, которые могут мешать измерениям.

-

Применение озоления

- Аналитическая химия: Озоление используется для минерализации и предварительного концентрирования следовых веществ перед химическим или оптическим анализом, таким как хроматография или спектроскопия.

- Пищевая промышленность: Оно помогает количественно определить минеральный состав пищевых образцов путем сжигания органических материалов.

- Нефтяная промышленность: Озоление обеспечивает горючесть нефтепродуктов путем проверки их содержимого.

- Анализ почвы: Оно определяет органическую долю почвы путем сравнения массы до и после озоления.

-

Распространенные методы озоления

- Сухое озоление: Включает нагревание образцов при высоких температурах (около 500°C) для сжигания органических веществ.

- Мокрое озоление: Использует кислоты вместо высоких температур для удаления органических компонентов, подходит для термочувствительных образцов.

- Низкотемпературное озоление: Проводится при более низких температурах (около 200°C) для сохранения термочувствительных элементов.

- Сульфатное озоление: Нейтрализует и удаляет диоксид серы из образцов.

- Озоление в закрытой системе: Использует герметичные камеры для контроля атмосферы во время процесса, обеспечивая точность.

-

Роль в атомно-абсорбционной спектрометрии с графитовой печью (АА)

- Озоление является важным этапом в программах АА с графитовой печью, где оно удаляет компоненты матрицы, которые могут мешать измерению аналита.

- Этот этап обеспечивает точные и надежные результаты элементного анализа.

-

Важность в подготовке образцов

- Озоление упрощает матрицы образцов, облегчая анализ остаточной золы на элементный состав.

- Особенно полезно для предварительного концентрирования следовых веществ, повышая чувствительность аналитических методов.

-

Оборудование, используемое при озолении

- Лабораторные муфельные печи для озоления: Предназначены для измерения изменений веса образцов по мере выгорания органических компонентов.

- Эти печи необходимы для отраслей, требующих точного количественного определения минерального или органического содержания.

-

Преимущества озоления

- Обеспечивает точный анализ путем удаления мешающих веществ.

- Предоставляет чистую матрицу образца для таких методов, как спектроскопия и хроматография.

- Помогает в количественном определении содержания минералов и органических пропорций в различных материалах.

Понимая эти ключевые моменты, покупатели оборудования и расходных материалов могут лучше оценить важность озоления в подготовке и анализе образцов, гарантируя выбор правильных инструментов и методов для своих конкретных потребностей.

Сводная таблица:

| Аспект | Подробности |

|---|---|

| Назначение | Удаляет органические вещества, оставляя несгораемую золу для анализа. |

| Применение | Аналитическая химия, пищевая промышленность, испытания нефтепродуктов, анализ почвы. |

| Методы | Сухое озоление, мокрое озоление, низкотемпературное озоление, сульфатное озоление. |

| Оборудование | Лабораторные муфельные печи для озоления для точного измерения веса. |

| Преимущества | Обеспечивает точный анализ, упрощает матрицы образцов, повышает чувствительность. |

Нужно подходящее оборудование для озоления для вашей лаборатории? Свяжитесь с нами сегодня для получения экспертной консультации и решений!

Визуальное руководство

Связанные товары

- Муфельная печь 1800℃ для лаборатории

- Муфельная печь 1700℃ для лаборатории

- Лабораторная муфельная печь с нижним подъемом

- Муфельная печь 1400℃ для лаборатории

- Печь-муфель с высокой температурой для обезжиривания и предварительного спекания в лаборатории

Люди также спрашивают

- Какова взаимосвязь между температурой спекания и температурой плавления? Ключевые различия для инженеров-материаловедов

- Какие 4 типа термообработки проходит сталь? Полный отжиг, нормализация, закалка и отпуск

- Каковы недостатки мокрого озоления? Ключевые риски безопасности и загрязнения

- Какие существуют типы анализа золы? Объяснение методов сухого и мокрого озоления

- Каковы 2 преимущества сухого озоления? Достижение высокопроизводительного анализа образцов с безопасностью