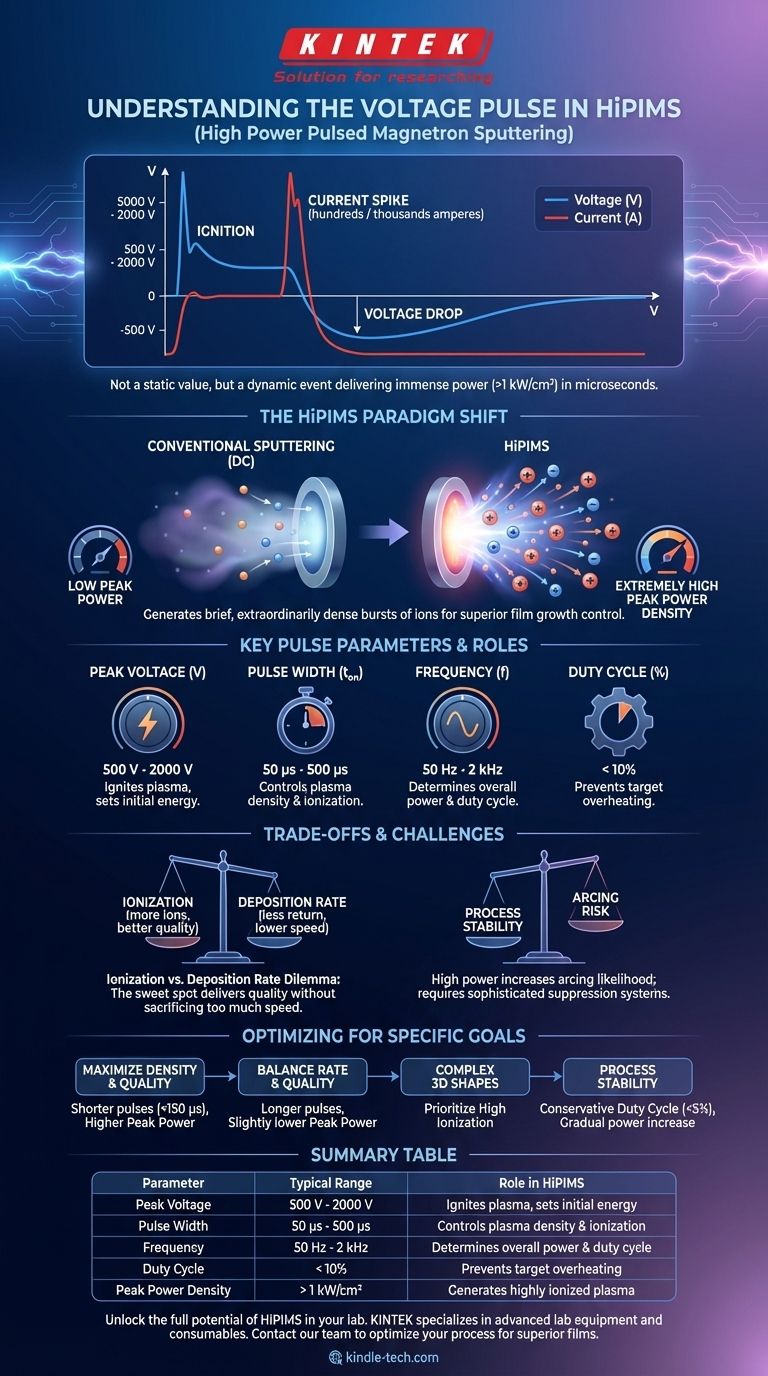

При магнетронном распылении с высокой мощностью в импульсном режиме (HiPIMS) импульсное напряжение — это не просто статичное значение, а динамическое событие, характеризующееся высокой пиковой мощностью и низким рабочим циклом. Хотя начальное напряжение может варьироваться от 500 В до 2000 В, ключевым моментом является подача огромной мощности (часто >1 кВт/см²) очень короткими импульсами (микросекунды) для создания высокоионизированной плазмы.

Ключевой вывод заключается в том, что импульс напряжения HiPIMS — это инструмент для контроля плотности плазмы и ионизации распыляемого материала. Вместо того чтобы фокусироваться на одном значении напряжения, вы должны управлять взаимосвязью между напряжением, током, длительностью импульса и частотой, чтобы достичь желаемых свойств пленки.

От напряжения к плотности мощности: Смена парадигмы HiPIMS

HiPIMS представляет собой фундаментальный отход от традиционных методов распыления, таких как постоянный ток (DC) или радиочастотный (RF). Цель состоит не просто в создании устойчивой плазмы, а в генерации кратковременного, чрезвычайно плотного выброса ионов.

Почему HiPIMS — это не просто «Импульсный DC»

Определяющей особенностью HiPIMS является чрезвычайно высокая пиковая плотность мощности на поверхности мишени, часто на два или три порядка выше, чем при магнетронном распылении постоянным током.

Этот интенсивный всплеск мощности создает плазму с очень высокой долей ионизированных распыленных атомов. Затем этими ионами можно управлять с помощью электрических или магнитных полей, что обеспечивает превосходный контроль над ростом пленки.

Анатомия импульса HiPIMS

Типичный импульс HiPIMS имеет четкую электрическую сигнатуру.

- Зажигание: Импульс начинается с подачи высокого напряжения на мишень, но ток вначале низкий, поскольку плазма еще не сформировалась.

- Скачок тока: По мере пробоя газа и развития плотной плазмы импеданс плазмы резко падает. Это вызывает массивный скачок тока, который может достигать сотен или даже тысяч ампер.

- Падение напряжения: Из-за резкого увеличения тока и ограничений источника питания напряжение на плазме одновременно падает в течение основной фазы импульса.

Эта динамическая V-I характеристика является отличительной чертой разряда HiPIMS.

Ключевые параметры импульса и их роль

Управление процессом означает управление этими четырьмя взаимосвязанными параметрами:

- Пиковое напряжение (V): Начальное напряжение, подаваемое для зажигания плазмы, обычно от 500 В до 2000 В.

- Длительность импульса (t_on): Продолжительность импульса, обычно от 50 мкс до 500 мкс.

- Частота (f): Количество импульсов в секунду, обычно в диапазоне от 50 Гц до 2 кГц.

- Рабочий цикл: Процент времени, в течение которого подается питание (

t_on * f). Он почти всегда поддерживается ниже 10%, чтобы предотвратить перегрев и плавление мишени.

Как характеристики импульса определяют ваш процесс

Настройка импульса напряжения дает вам прямой контроль над плазменной средой и, следовательно, над свойствами нанесенной пленки.

Влияние на долю ионизации

Более короткие, более интенсивные импульсы с более высокой пиковой плотностью мощности приводят к более высокой доле ионизации. Более высокая доля ионизированного потока осаждения является основным преимуществом HiPIMS, позволяя выращивать исключительно плотные и гладкие пленки с отличной адгезией.

Влияние на скорость нанесения

Высокая ионизация в HiPIMS иногда может привести к более низкой скорости нанесения по сравнению с распылением постоянным током. Это связано с тем, что часть вновь созданных ионов металла притягивается обратно к отрицательно смещенной мишени, что называется возвратом ионов или самораспылением. Регулировка длительности импульса и мощности может помочь найти баланс между высокой ионизацией и приемлемой скоростью нанесения.

Контроль свойств пленки

Энергичная бомбардировка ионами, обеспечиваемая HiPIMS, позволяет манипулировать растущей пленкой на атомном уровне. Контролируя импульс, вы можете точно настраивать такие свойства пленки, как кристалличность, плотность, твердость и внутренние напряжения. Это особенно полезно для создания сложных оптических покрытий или твердых защитных слоев.

Понимание компромиссов и проблем

Хотя HiPIMS является мощным инструментом, он не является универсальным решением и сопряжен с присущими ему сложностями, требующими тщательного управления.

Дилемма: Скорость нанесения против ионизации

Это центральный компромисс в HiPIMS. Условия, создающие наивысшую ионизацию (очень высокая мощность, короткие импульсы), также имеют тенденцию максимизировать эффект возврата ионов, тем самым снижая скорость нанесения. Оптимизация процесса часто включает поиск «золотой середины», которая обеспечивает достаточный поток ионов для желаемого качества пленки без чрезмерной потери производительности.

Стабильность процесса и дугообразование

Чрезвычайно высокие уровни мощности, используемые в HiPIMS, увеличивают вероятность дугообразования на поверхности мишени. Современные источники питания HiPIMS включают сложные системы обнаружения и подавления дуги, которые могут погасить дугу за микросекунды, но это остается ключевым фактором, который необходимо учитывать в процессе.

Динамика импеданса системы

Импеданс плазмы резко меняется в течение одного импульса. Источник питания должен уметь справляться с этой динамической нагрузкой, подавая высокое напряжение в разомкнутую цепь для начала импульса, а затем переходя к подаче огромного тока в плазму с низким импедансом.

Оптимизация импульса для конкретных целей

Выбор параметров импульса должен определяться основной целью вашего процесса нанесения.

- Если ваша основная цель — максимальная плотность и качество пленки: Используйте более короткую длительность импульсов (например, < 150 мкс) и более высокую пиковую мощность для создания максимально возможной доли ионизации для превосходного уплотнения пленки.

- Если ваша основная цель — баланс между скоростью нанесения и качеством: Экспериментируйте с более длительной длительностью импульсов или немного более низкой пиковой мощностью, чтобы уменьшить эффект возврата ионов и увеличить чистую скорость нанесения.

- Если ваша основная цель — нанесение покрытия на сложные 3D-формы: Отдавайте приоритет высокой ионизации, чтобы гарантировать, что поток осаждения может эффективно направляться для конформного покрытия всех поверхностей, даже тех, которые не находятся в прямой видимости мишени.

- Если ваша основная цель — стабильность процесса: Начните с консервативного рабочего цикла (<5%) и постепенно увеличивайте мощность, контролируя формы напряжения и тока, чтобы установить стабильное рабочее окно с минимальным дугообразованием.

Выйдя за рамки простой настройки напряжения, вы начнете осваивать импульс HiPIMS, получая беспрецедентный контроль над фундаментальными свойствами вашей тонкой пленки на атомном уровне.

Сводная таблица:

| Параметр | Типичный диапазон | Роль в HiPIMS |

|---|---|---|

| Пиковое напряжение | 500 В - 2000 В | Зажигает плазму, задает начальную энергию |

| Длительность импульса | 50 мкс - 500 мкс | Контролирует плотность плазмы и ионизацию |

| Частота | 50 Гц - 2 кГц | Определяет общую мощность и рабочий цикл |

| Рабочий цикл | < 10% | Предотвращает перегрев мишени |

| Пиковая плотность мощности | > 1 кВт/см² | Создает высокоионизированную плазму |

Раскройте весь потенциал HiPIMS в вашей лаборатории. KINTEK специализируется на современном лабораторном оборудовании и расходных материалах для нанесения тонких пленок. Наши эксперты могут помочь вам выбрать подходящую систему магнетронного распыления и оптимизировать ваш процесс HiPIMS для достижения превосходной плотности пленки, адгезии и конформного покрытия на сложных подложках. Свяжитесь с нашей командой сегодня, чтобы обсудить ваши конкретные потребности в применении и узнать, как наши решения могут улучшить результаты ваших исследований и производства.

Визуальное руководство

Связанные товары

- Наклонная роторная установка для плазменно-усиленного химического осаждения из паровой фазы PECVD

- Оборудование системы HFCVD для нанесения наноалмазного покрытия на волочильные фильеры

- 915 МГц MPCVD Алмазная установка Микроволновая плазменная химическая осаждение из газовой фазы Система реактора

- Пресс-форма против растрескивания для лабораторного использования

- Лабораторный стерилизатор Автоклав Импульсный вакуумный подъемный стерилизатор

Люди также спрашивают

- Какие существуют типы тонких пленок? Руководство по функциям, материалам и методам осаждения

- Как системы PECVD улучшают DLC-покрытия на имплантатах? Объяснение превосходной долговечности и биосовместимости

- Каковы технологические возможности систем ICPCVD? Достижение низкотемпературного осаждения пленок с низким уровнем повреждений при сверхнизких температурах

- Почему вакуумная система PECVD требует как пластинчато-роторного, так и турбомолекулярного насоса? Обеспечение высокочистых покрытий

- Почему согласующее устройство является неотъемлемой частью RF-PECVD для силоксановых пленок? Обеспечение стабильной плазмы и равномерного осаждения