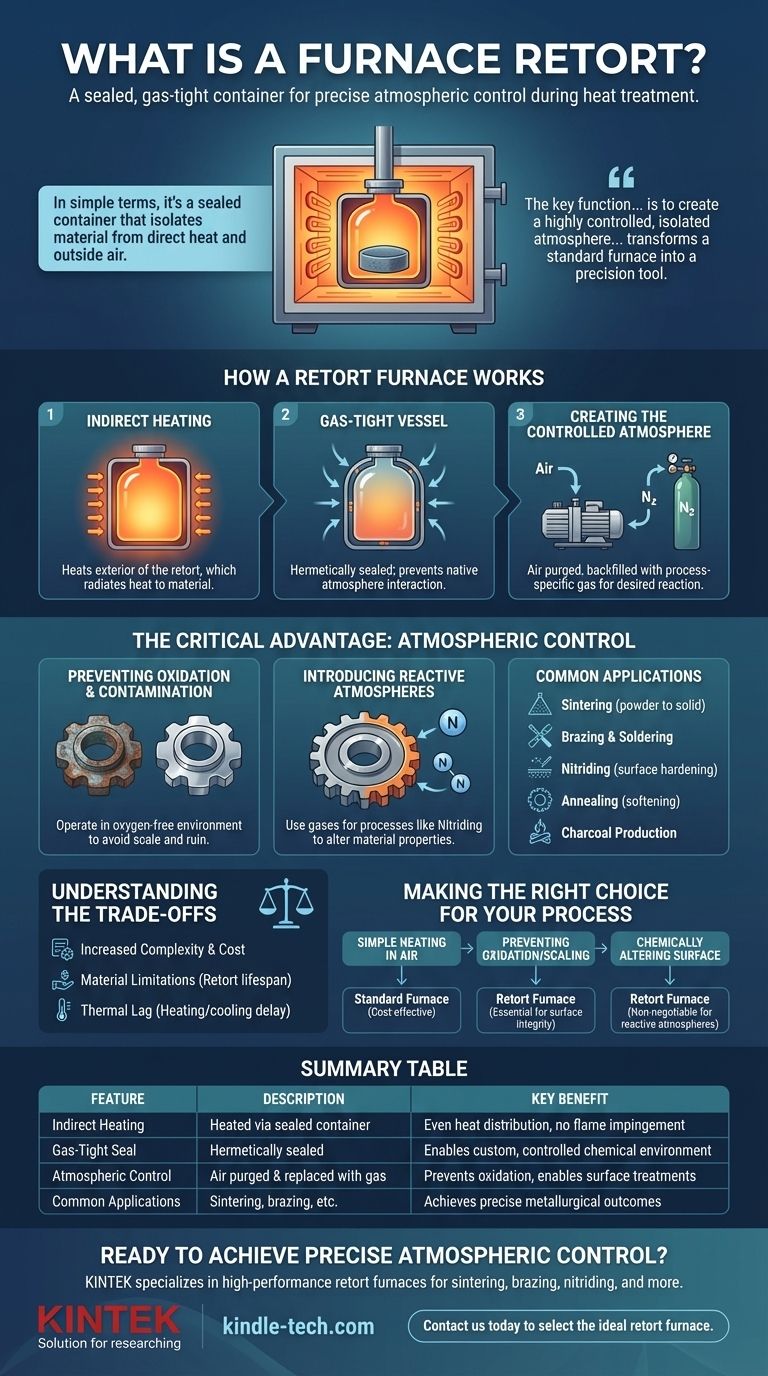

Проще говоря, реторта печи — это герметичный, газонепроницаемый контейнер, помещенный внутрь печи. Ее цель — изолировать обрабатываемый материал от прямого источника тепла и наружного воздуха. Это разделение позволяет точно контролировать химическую атмосферу вокруг материала во время термообработки, что критически важно для многих передовых процессов.

Ключевая функция реторты печи заключается не просто в удержании материала, а в создании вокруг него высококонтролируемой, изолированной атмосферы. Это превращает стандартную печь в прецизионный инструмент для специализированных термических процессов, где химическая среда так же важна, как и сама температура.

Как работает печь с ретортой

Печь с ретортой работает по принципу непрямого нагрева и атмосферной изоляции. Понимание этой основной концепции является ключом к оценке ее ценности.

Принцип: Непрямой нагрев

Нагревательные элементы печи — либо электрические резистивные нагреватели, либо газовые горелки — не нагревают целевой материал напрямую. Вместо этого они нагревают внешнюю часть реторты.

Реторта, обычно изготовленная из жаропрочной стали или никелевого сплава, поглощает это тепло и равномерно передает его материалу, находящемуся внутри.

Газонепроницаемый сосуд

Определяющей особенностью реторты является ее герметичность. Эта герметичность предотвращает взаимодействие атмосферы самой печи (или наружного воздуха) с заготовкой.

Эта конструкция позволяет операторам создавать настраиваемую атмосферу внутри реторты. Воздух может быть вытеснен и заменен определенным газом или газовой смесью для достижения желаемой химической реакции или предотвращения нежелательной.

Создание контролируемой атмосферы

После загрузки материала и герметизации реторты может быть создано разрежение для удаления всего воздуха. После этого камеру можно заполнить газом, специфичным для процесса.

Например, для азотирования используется атмосфера, богатая азотом, в то время как инертный газ, такой как аргон, может использоваться для предотвращения каких-либо химических изменений во время нагрева.

Критическое преимущество: Контроль атмосферы

Возможность манипулировать атмосферой — вот почему печи с ретортами необходимы для определенных применений. Без этого контроля многие современные методы обработки материалов были бы невозможны.

Предотвращение окисления и загрязнения

Наиболее распространенное применение контролируемой атмосферы — предотвращение окисления. При высоких температурах многие металлы реагируют с кислородом в воздухе, образуя слой окалины, который может испортить чистоту поверхности и точность размеров детали.

Работая в бескислородной среде, материалы можно нагревать и охлаждать без такого разрушения. Это часто называют «ярким отжигом».

Введение реактивных сред

Помимо простого предотвращения, печи с ретортами позволяют вводить реактивные газы для преднамеренного изменения свойств материала.

Такие процессы, как азотирование, вводят азот для упрочнения поверхности стали. Другие процессы могут использовать водород или газы, богатые углеродом, для достижения специфических металлургических результатов.

Общие области применения

Этот уровень контроля делает печи с ретортами незаменимыми для:

- Спекание: Сплавление порошковых металлов без их плавления.

- Пайка и твердая пайка: Соединение металлов в чистой среде без флюса.

- Азотирование: Поверхностное упрочнение стали.

- Отжиг: Размягчение металлов и снятие внутренних напряжений.

- Производство древесного угля: Нагрев древесины в отсутствие кислорода.

Понимание компромиссов

Несмотря на свою мощность, конструкция печи с ретортой не всегда необходима и сопряжена с определенными особенностями.

Повышенная сложность и стоимость

Необходимость в высокогерметичном уплотнении, системах подачи газа и протоколах продувки делает печь с ретортой более сложной и дорогой, чем простая печь с воздушным нагревом. Сама реторта является расходным компонентом, который со временем изнашивается из-за термических циклов.

Ограничения по материалам

Реторта изготавливается из специальных высокотемпературных сплавов, способных выдерживать экстремальные условия. Однако даже эти материалы имеют пределы по температуре и сроку службы, что может ограничивать рабочий диапазон печи и увеличивать затраты на техническое обслуживание.

Тепловая инерция

Поскольку тепло должно сначала пройти через стенку реторты, чтобы достичь заготовки, может наблюдаться небольшая задержка в циклах нагрева и охлаждения по сравнению с печами прямого нагрева. Это незначительный компромисс по сравнению с огромной выгодой от контроля атмосферы.

Выбор правильного решения для вашего процесса

Решение о том, нужна ли вам печь с ретортой, зависит от химических требований вашего конкретного термического процесса.

- Если ваша основная цель — простой нагрев на воздухе: Стандартная печь без реторты более экономична и проста для процессов, где окисление поверхности допустимо или желательно.

- Если ваша основная цель — предотвращение окисления или образования окалины: Печь с ретортой необходима для сохранения целостности поверхности и внешнего вида чувствительных материалов, таких как нержавеющая сталь или медные сплавы.

- Если ваша основная цель — химическое изменение поверхности материала: Реторта является обязательной для таких процессов, как азотирование или науглероживание, которые требуют определенной реактивной газовой среды.

В конечном счете, понимание функции реторты позволяет вам выбрать не просто нагревательное устройство, а точную атмосферную среду, необходимую для вашего процесса.

Сводная таблица:

| Характеристика | Описание | Ключевое преимущество |

|---|---|---|

| Непрямой нагрев | Материал нагревается через герметичный контейнер (реторту) внутри печи. | Предотвращает прямое воздействие пламени и обеспечивает равномерное распределение тепла. |

| Газонепроницаемое уплотнение | Реторта герметично закрыта, изолируя заготовку от атмосферы печи. | Позволяет создавать настраиваемую, контролируемую химическую среду (например, азот, аргон). |

| Контроль атмосферы | Воздух вытесняется и заменяется специфической газовой смесью для процесса. | Важно для предотвращения окисления (яркий отжиг) или обеспечения поверхностной обработки (азотирование). |

| Общие области применения | Спекание, пайка, отжиг, азотирование, производство древесного угля. | Достижение точных металлургических результатов, невозможных в стандартной воздушной среде. |

Готовы добиться точного контроля атмосферы в вашей лаборатории?

Если ваши термические процессы требуют защиты от окисления или специфической реактивной газовой среды, печь с ретортой — это необходимое решение. KINTEK специализируется на высокопроизводительном лабораторном оборудовании, включая печи с ретортами, предназначенные для спекания, пайки, азотирования и многого другого.

Мы предоставляем правильное оборудование, чтобы гарантировать, что ваши материалы обрабатываются в идеальной атмосфере, обеспечивая превосходные результаты и повторяемость.

Свяжитесь с нами сегодня, чтобы обсудить ваше конкретное применение, и позвольте нашим экспертам помочь вам выбрать идеальную печь с ретортой для ваших лабораторных нужд.

Визуальное руководство

Связанные товары

- Вакуумная герметичная ротационная трубчатая печь непрерывного действия

- Лабораторная трубчатая печь высокой температуры 1700℃ с алюминиевой трубкой

- Роторная трубчатая печь с разделенными многозонными нагревательными зонами

- Вертикальная лабораторная трубчатая печь

- Лабораторная вакуумная наклонно-вращательная трубчатая печь Вращающаяся трубчатая печь

Люди также спрашивают

- Какие факторы влияют на выход биомасла при пиролизе скорлупы кокоса? Контролируйте 4 ключевых параметра

- Каковы технологические преимущества использования роторной трубчатой печи для порошка WS2? Достижение превосходной кристалличности материала

- Каковы требования к оборудованию для загрузки платины (Pt) на композитные носители? Точное перемешивание для высокой дисперсности

- Как высокотемпературные реакционные печи контролируют внутренние металломатричные композиты (MMC)? Обеспечение точности материалов и структурной целостности

- Какая температура необходима для пиролиза отходов? Руководство по оптимизации процесса превращения отходов в ценные продукты