Да, муфельная печь должна быть правильно вентилируемой. Это не просто рекомендация, а критическое требование для безопасной эксплуатации, долговечности оборудования и целостности вашей работы. Система вентиляции предназначена для активного удаления потенциально опасных или коррозионных паров и газов, выделяющихся из материалов в процессе высокотемпературного нагрева.

Вентиляция муфельной печи — это обязательный этап эксплуатации. Она выполняет две основные, одинаково важные функции: защита оператора от потенциально токсичных паров и защита внутренних компонентов печи от коррозионных побочных продуктов самого процесса нагрева.

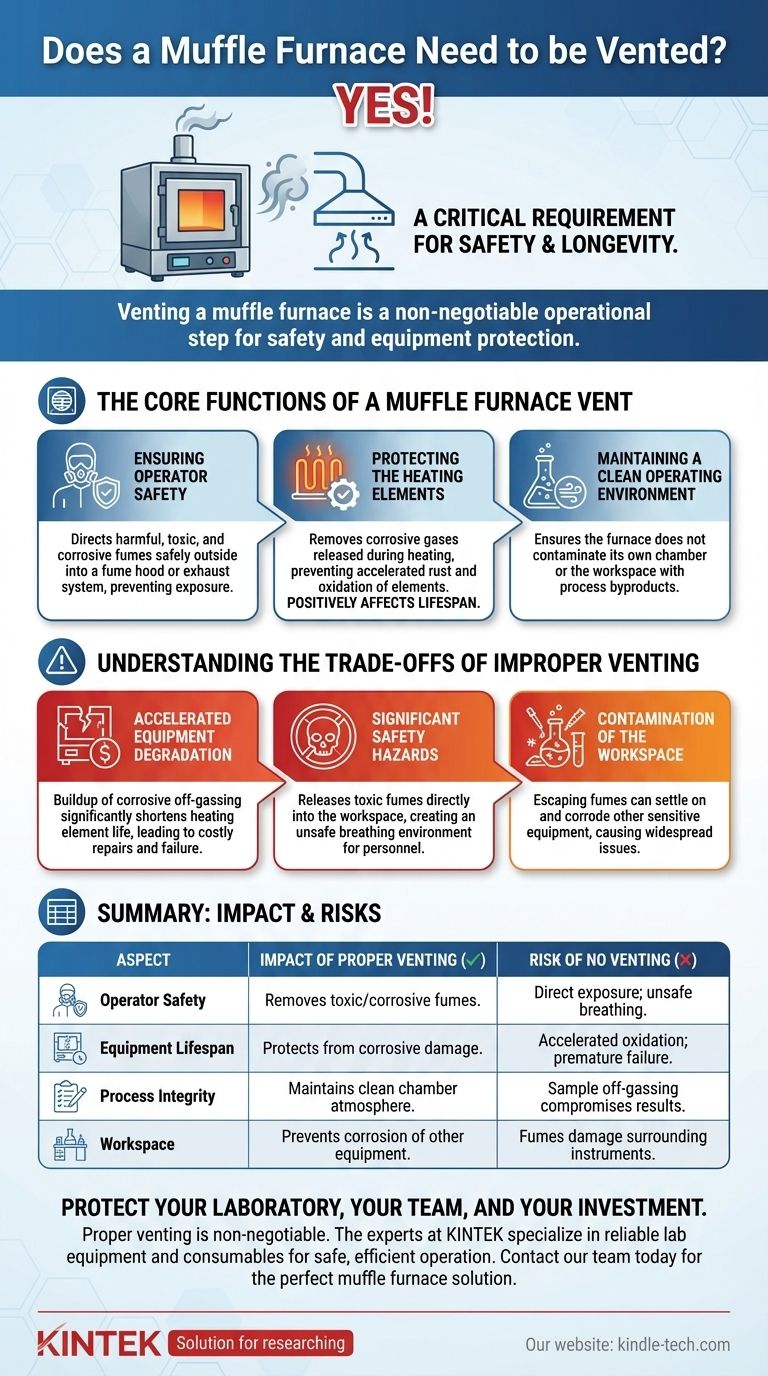

Основные функции вентиляции муфельной печи

Понимание того, почему вентиляция необходима, требует рассмотрения ее влияния на безопасность, оборудование и окружающую среду.

Обеспечение безопасности оператора

Многие процессы, выполняемые в муфельной печи, такие как прокаливание органических веществ или термообработка материалов с покрытиями, выделяют пары. Эти побочные продукты могут быть токсичными, коррозионными или создавать атмосферу с дефицитом кислорода, если им позволить накапливаться в рабочей зоне.

Правильная вытяжка безопасно отводит эти вредные выбросы наружу, как правило, в лабораторный вытяжной шкаф или специальную вытяжную систему.

Защита нагревательных элементов

Газы и пары, выделяющиеся из образцов при высоких температурах, могут быть высококоррозионными. Если эти побочные продукты не удаляются, они остаются запертыми внутри камеры печи.

Эта коррозионная среда напрямую воздействует на электрические нагревательные элементы, вызывая их ускоренную ржавчину и окисление. Как указано в технической документации, вентиляция является прямым фактором, который положительно влияет на срок службы элементов.

Поддержание чистой рабочей среды

Муфельная печь спроектирована для работы в среде, свободной от коррозионных газов и легковоспламеняющихся материалов. Система вентиляции имеет решающее значение для обеспечения того, чтобы печь не загрязняла собственную рабочую среду теми же веществами, от которых она должна быть защищена.

Понимание последствий неправильной вентиляции

Отказ от вентиляции муфельной печи — это не мера экономии; это решение, которое влечет за собой значительные риски и скрытые затраты.

Ускоренная деградация оборудования

Самым непосредственным последствием отсутствия вентиляции является повреждение самой печи. Накопление коррозионных отходящих газов значительно сократит срок службы нагревательных элементов, что приведет к преждевременному выходу из строя и дорогостоящему ремонту.

Значительные угрозы безопасности

Без вентиляции все технологические пары выбрасываются непосредственно в вашу рабочую зону. Это подвергает персонал воздействию потенциально токсичных химикатов и создает небезопасную среду для дыхания, что является недопустимым риском в любой профессиональной среде.

Загрязнение рабочего пространства

Пары, выходящие из печи, могут оседать на другом чувствительном оборудовании в помещении и вызывать его коррозию. Это может привести к широкомасштабным проблемам с оборудованием далеко за пределами самой печи.

Принятие правильного решения для вашего применения

Внедрение правильной стратегии вентиляции просто и необходимо для достижения ваших целей.

- Если ваш основной фокус — безопасность оператора: Не подлежащим обсуждению первым шагом является обеспечение активного отвода всех паров из вентиляционного отверстия печи в систему внешней вытяжки, например, в вытяжной шкаф.

- Если ваш основной фокус — долговечность оборудования: Постоянное использование воздушного вентиляционного отверстия печи предотвращает накопление коррозионных газов, напрямую защищая нагревательные элементы от окисления и максимально увеличивая срок службы агрегата.

- Если ваш основной фокус — точность процесса: Правильная вентиляция гарантирует, что отходящие газы из вашего образца не создадут непреднамеренную и неконтролируемую атмосферу внутри камеры, которая может поставить под угрозу ваши результаты.

Правильная вентиляция вашей муфельной печи — это самый важный шаг для обеспечения безопасной, надежной и долговечной работы.

Сводная таблица:

| Аспект | Влияние правильной вентиляции | Риск отсутствия вентиляции |

|---|---|---|

| Безопасность оператора | Удаляет токсичные/коррозионные пары из рабочей зоны. | Прямое воздействие опасных паров; небезопасная среда для дыхания. |

| Срок службы оборудования | Защищает нагревательные элементы от коррозионного повреждения. | Ускоренное окисление и преждевременный выход из строя элементов. |

| Целостность процесса | Поддерживает чистую, контролируемую атмосферу в камере. | Выделение газов из образца может загрязнить и скомпрометировать результаты. |

| Рабочая зона | Предотвращает коррозию другого чувствительного лабораторного оборудования. | Пары могут оседать и повреждать окружающие приборы. |

Защитите свою лабораторию, свою команду и свои инвестиции. Правильная вентиляция является обязательным условием для безопасной и эффективной работы муфельной печи. Специалисты KINTEK могут помочь вам выбрать подходящую печь и обеспечить ее интеграцию с правильным вентиляционным решением для вашего конкретного применения.

Мы специализируемся на поставке надежного лабораторного оборудования и расходных материалов, обеспечивая безопасную и эффективную работу вашей лаборатории.

Свяжитесь с нашей командой сегодня, чтобы обсудить ваши потребности и найти идеальное решение по муфельной печи для вашей лаборатории.

Визуальное руководство

Связанные товары

- Лабораторная муфельная печь с нижним подъемом

- Муфельная печь 1800℃ для лаборатории

- Муфельная печь 1700℃ для лаборатории

- Муфельная печь 1400℃ для лаборатории

- Лабораторная трубчатая печь высокой температуры 1400℃ с корундовой трубкой

Люди также спрашивают

- Какова функция лабораторной печи при подготовке образцов стали W18Cr4V для микроструктурного анализа?

- Что такое зола в пищевой промышленности? Объяснение основных типов, методов и применений

- Как отпуск снижает твердость? Достижение идеального баланса между вязкостью и долговечностью

- Какова функция высокотемпературного термоотжига в муфельной печи? Оптимизация синтеза микросфер CeO2

- Что такое печь для определения зольности? Откройте для себя точный анализ минерального состава

- Какую роль играет высокотемпературная муфельная печь в производстве неорганических нановолокон оксида металла?

- Какую функцию выполняет муфельная печь в покрытиях LiNbO3 на NCA? Повышение стабильности катодного интерфейса

- Какова рабочая температура муфельной печи? От 200°C до 1800°C для вашего применения