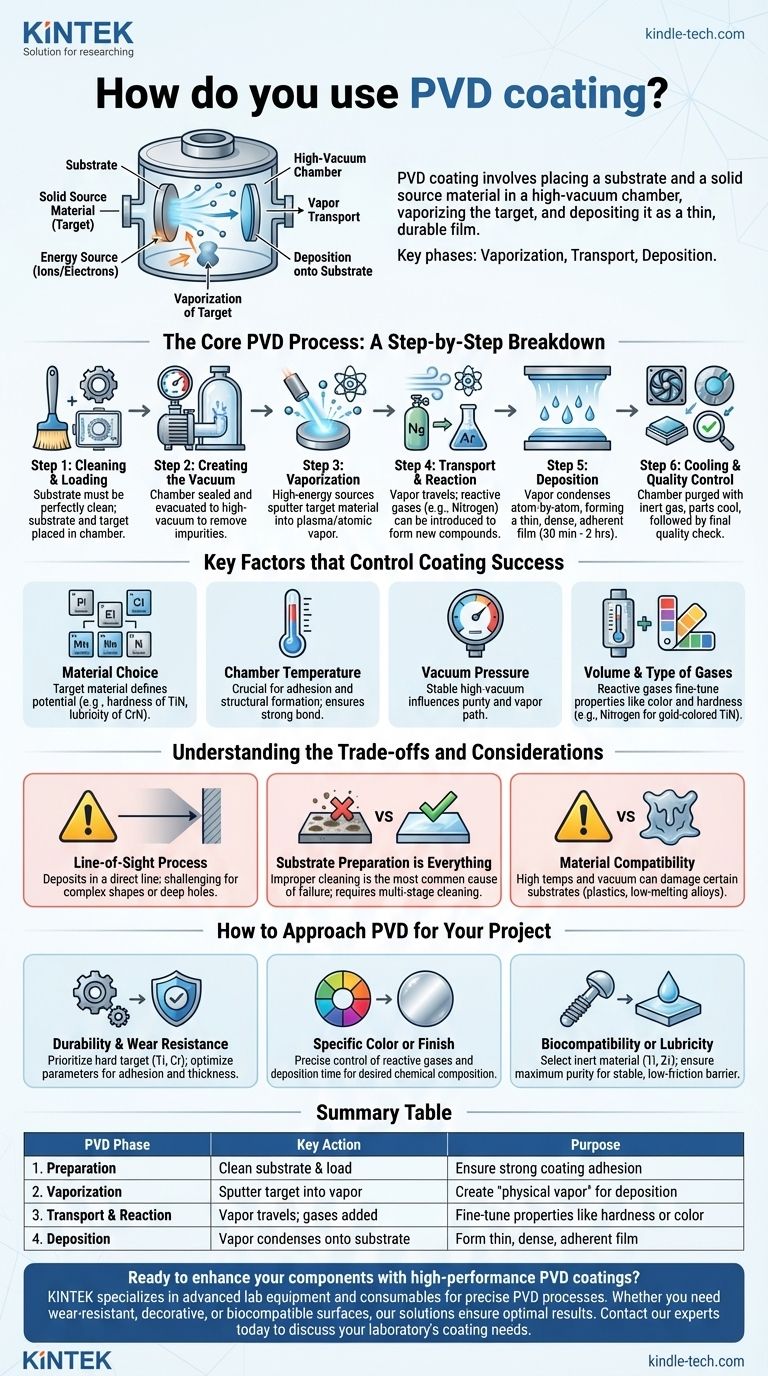

Для использования нанесения покрытий методом физического осаждения из паровой фазы (PVD) вы помещаете подложку и твердый исходный материал (мишень) внутрь вакуумной камеры высокого давления. Затем материал мишени испаряется с использованием энергии, такой как ионы или электроны, и этот пар проходит через вакуум, конденсируясь на подложке и образуя очень тонкую, прочную пленку. Весь процесс состоит из трех основных фаз: испарение мишени, перенос пара и осаждение на покрываемую деталь.

Процесс PVD — это не столько отдельный «метод нанесения», сколько точное управление сложной средой. Успех полностью зависит от манипулирования такими переменными, как температура, давление вакуума и реактивные газы, для создания покрытия с заданными свойствами, такими как твердость, цвет или сопротивление трению.

Основной процесс PVD: пошаговое описание

Процесс PVD является высокотехнологичным и происходит внутри герметичной вакуумной камеры. Хотя методы могут различаться, основные этапы остаются неизменными.

Шаг 1: Очистка и загрузка

Прежде чем начать процесс, компонент, который необходимо покрыть (подложка), должен быть идеально чистым. Любые поверхностные загрязнения помешают правильному прилипанию покрытия. Затем подложка и твердый материал мишени помещаются в вакуумную камеру.

Шаг 2: Создание вакуума

Камера герметизируется, и из нее откачивается воздух до чрезвычайно низкого давления. Эта среда высокого вакуума имеет решающее значение, поскольку она удаляет атмосферные газы и примеси, которые могут реагировать с испаренным материалом и нарушить целостность покрытия.

Шаг 3: Испарение

Используются источники высокой энергии для бомбардировки материала мишени, что приводит к выбросу или «распылению» его атомов в виде пара. Это «Физическое Осаждение из Паровой Фазы» (PVD). Этот шаг преобразует твердый исходный материал в плазму или атомный пар.

Шаг 4: Перенос и реакция

Испаренные атомы перемещаются через вакуумную камеру к подложке. На этом этапе могут вводиться реактивные газы (например, азот или аргон). Эти газы вступают в реакцию с металлическим паром, образуя новые соединения, что является ключом к определению конечных свойств покрытия.

Шаг 5: Осаждение

Испаренный материал конденсируется на поверхности подложки, атом за атомом. Это формирует тонкую, плотную и высокоадгезионную пленку. Весь процесс обычно занимает от 30 минут до двух часов, в зависимости от размера детали и желаемой толщины.

Шаг 6: Охлаждение и контроль качества

После достижения желаемой толщины источник энергии отключается, и камера продувается инертным газом. Покрытым деталям дают остыть, прежде чем извлечь их для окончательной проверки качества, чтобы обеспечить полное и равномерное покрытие.

Ключевые факторы, определяющие успех покрытия

Достижение определенного результата с помощью PVD не случайно. Это результат тщательного контроля нескольких ключевых переменных в процессе.

Выбор материала покрытия

Материал мишени фундаментально определяет потенциал покрытия. Материалы выбираются по их присущим свойствам, таким как твердость нитрида титана или смазывающая способность нитрида хрома.

Температура камеры

Контроль температуры имеет решающее значение. Он влияет на адгезию покрытия к подложке и структурное формирование самой пленки. Правильная температура обеспечивает прочную, долговечную связь.

Давление вакуума

Уровень вакуума должен быть подходящим и стабильным на протяжении всего процесса. Давление влияет на чистоту покрытия и путь, по которому испаренные атомы достигают подложки.

Объем и тип газов

Введение реактивных газов — это способ точной настройки таких свойств, как цвет и твердость. Например, добавление азота к пару титана создает широко известный золотистый нитрид титана (TiN), который чрезвычайно тверд.

Понимание компромиссов и соображений

Хотя PVD является мощным инструментом, он не является универсальным решением. Понимание его ограничений является ключом к его эффективному использованию.

Это процесс с прямой видимостью

PVD наносит материал по прямой линии от источника к подложке. Это может затруднить равномерное покрытие внутренней части сложных форм или глубоких узких отверстий без использования специальных приспособлений и вращения детали.

Подготовка подложки — это главное

Самая распространенная причина неудачи нанесения покрытия PVD — неправильная подготовка поверхности. Подложка должна быть хирургически чистой, чтобы покрытие правильно прилипло. Это часто требует многоступенчатых процессов очистки и предварительной обработки.

Совместимость материалов

Не все материалы подходят для нанесения покрытий методом PVD. Высокие температуры и вакуумная среда могут повредить или изменить некоторые подложки, особенно пластики или сплавы с низкой температурой плавления.

Как подойти к PVD для вашего проекта

Выбор правильных параметров PVD полностью зависит от вашей конечной цели. Процесс может быть адаптирован для удовлетворения широкого спектра требований к производительности и эстетике.

- Если ваш основной акцент делается на долговечности и износостойкости: Отдавайте приоритет твердому материалу мишени, такому как титан или хром, и убедитесь, что параметры процесса оптимизированы для сильной адгезии и достаточной толщины.

- Если ваш основной акцент делается на определенном цвете или отделке: Ваш успех будет зависеть от точного контроля реактивных газов и времени осаждения для достижения желаемого химического состава на поверхности.

- Если ваш основной акцент делается на биосовместимости или смазывающей способности: Выберите инертный материал, такой как титан или цирконий, и запустите процесс, который обеспечивает максимальную чистоту для создания стабильного барьера, снижающего трение.

Понимая эти основные принципы, вы можете использовать процесс PVD не просто как покрытие, а как неотъемлемую часть проектирования и производительности вашего продукта.

Сводная таблица:

| Фаза PVD | Ключевое действие | Назначение |

|---|---|---|

| 1. Подготовка | Очистка подложки и загрузка в вакуумную камеру | Обеспечение прочной адгезии покрытия |

| 2. Испарение | Использование энергии для распыления материала мишени в пар | Создание «физического пара» для осаждения |

| 3. Перенос и реакция | Пар перемещается; могут быть добавлены реактивные газы (например, азот) | Тонкая настройка таких свойств, как твердость или цвет |

| 4. Осаждение | Пар конденсируется атом за атомом на подложке | Формирование тонкой, плотной и высокоадгезионной пленки |

Готовы улучшить свои компоненты с помощью высокоэффективных покрытий PVD? KINTEK специализируется на передовом лабораторном оборудовании и расходных материалах для точных процессов PVD. Независимо от того, нужны ли вам износостойкие, декоративные или биосовместимые поверхности, наши решения обеспечивают оптимальные результаты. Свяжитесь с нашими экспертами сегодня, чтобы обсудить, как мы можем поддержать потребности вашей лаборатории в нанесении покрытий.

Визуальное руководство

Связанные товары

- Наклонная роторная установка для плазменно-усиленного химического осаждения из паровой фазы PECVD

- Система ВЧ-PECVD Радиочастотное плазменно-усиленное химическое осаждение из газовой фазы ВЧ-PECVD

- Оборудование для осаждения из паровой фазы CVD Система Камерная Печь-труба PECVD с Жидкостным Газификатором Машина PECVD

- Тигель из бескислородной меди для нанесения покрытий методом электронно-лучевого испарения и испарительная лодочка

- Вакуумная печь горячего прессования для ламинирования и нагрева

Люди также спрашивают

- В чем разница между PECVD и CVD? Выберите правильный метод осаждения тонких пленок

- Какие материалы осаждаются методом PECVD? Откройте для себя универсальные тонкопленочные материалы для вашего применения

- Что такое осаждение кремния методом PECVD? Получение высококачественных тонких пленок при низких температурах

- Что такое осаждение из паровой фазы? Руководство по технологии нанесения покрытий на атомном уровне

- Для чего используется PECVD? Создание низкотемпературных, высокопроизводительных тонких пленок