Основное преимущество химического осаждения из газовой фазы (CVD) перед термическим окислением заключается в его глубокой универсальности. В то время как окисление является узкоспециализированным процессом, который выращивает один материал (диоксид кремния) из кремниевой подложки, CVD — это гибкая техника, которая может осаждать огромное количество различных материалов практически на любую подложку. Это делает CVD незаменимым инструментом для создания сложных, многослойных структур современной электроники.

Выбор между CVD и окислением заключается не в том, какой процесс универсально «лучше», а в понимании их фундаментальных целей. Окисление выращивает высококачественный собственный материал, расходуя подложку, в то время как CVD осаждает отдельный материал поверх нее.

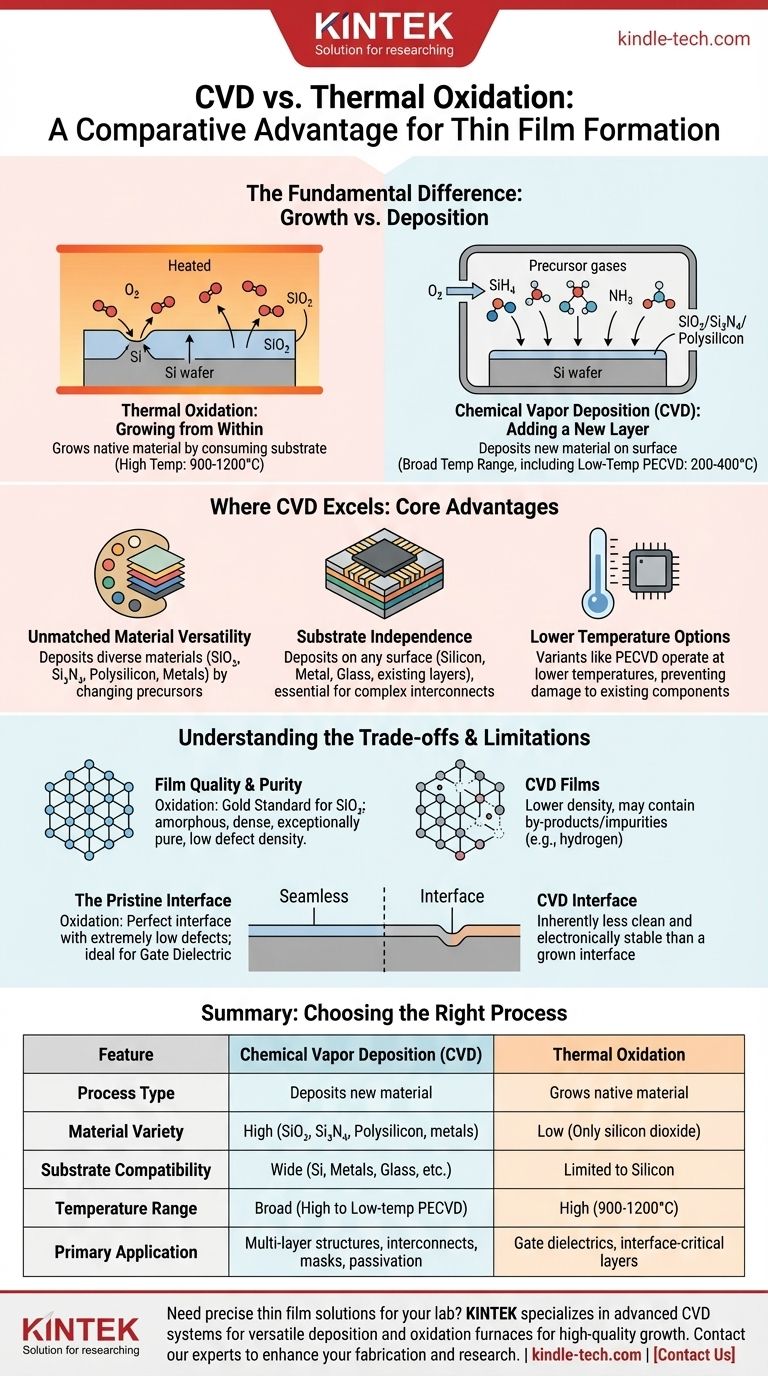

Фундаментальное различие: Рост против Осаждения

Чтобы понять преимущества каждого метода, вы должны сначала понять их основные механизмы. Они не взаимозаменяемы; это принципиально разные способы формирования тонкой пленки.

Термическое окисление: Рост изнутри

Термическое окисление — это процесс роста. Кремниевая пластина нагревается до высокой температуры (обычно 900-1200°C) в среде, содержащей кислород или водяной пар.

Атомы кремния на поверхности пластины реагируют с кислородом, расходуя исходный кремний для образования нового слоя диоксида кремния (SiO₂). Этот процесс сродни заживлению кожи — новый слой образуется непосредственно из подлежащего материала.

Химическое осаждение из газовой фазы: Добавление нового слоя

CVD — это процесс осаждения. Газы-прекурсоры вводятся в реакционную камеру, где они химически реагируют и разлагаются, оставляя твердую тонкую пленку на поверхности пластины.

Этот процесс не расходует подложку. Это похоже на покраску стены — вы добавляете совершенно новый материал поверх существующей поверхности. Это позволяет создавать пленки, которые химически отличаются от подложки.

В чем превосходит CVD: Основные преимущества

Природа CVD, основанная на осаждении, дает ей несколько критических преимуществ перед окислением для широкого спектра применений в производстве полупроводников.

Непревзойденная универсальность материалов

Окисление может создавать только один материал: диоксид кремния из кремниевой пластины.

CVD, однако, может осаждать огромное разнообразие материалов, просто меняя газы-прекурсоры. Это включает диэлектрики, такие как диоксид кремния (SiO₂) и нитрид кремния (Si₃N₄), полупроводники, такие как поликремний, и даже металлы.

Независимость от подложки

Процесс окисления полностью зависит от наличия кремниевой подложки для расхода. Вы не можете использовать его для формирования оксидного слоя поверх металлической линии или нитридной пленки.

CVD не имеет таких ограничений. Он может осаждать пленку на кремний, металл, стекло или другие ранее осажденные слои, что делает его незаменимым для создания многоуровневых межсоединений в современных чипах.

Варианты с более низкой температурой

Высокотемпературное термическое окисление может повредить другие компоненты на частично изготовленном чипе, такие как алюминиевые межсоединения.

Хотя некоторые процессы CVD являются высокотемпературными, варианты, такие как плазменно-усиленное CVD (PECVD), могут работать при гораздо более низких температурах (например, 200-400°C), что делает их безопасными для более поздних этапов изготовления.

Понимание компромиссов

Выбор процесса требует признания его ограничений. Хотя пленки CVD универсальны, они не могут сравниться с уникальным качеством термически выращенного оксида для его конкретной цели.

Качество и чистота пленки

Для создания диоксида кремния термическое окисление является золотым стандартом. Оно производит аморфную, плотную и исключительно чистую пленку с очень низкой плотностью дефектов.

Осажденные CVD оксиды, хотя и очень хороши, часто имеют более низкую плотность и могут содержать побочные продукты химической реакции, такие как примеси водорода.

Идеальный интерфейс

Это наиболее критическое различие. Поскольку термический оксид выращивается из кремния, интерфейс между кристаллом кремния и слоем диоксида кремния почти идеален, с чрезвычайно малым количеством электронных дефектов.

Интерфейс, созданный CVD, — это просто место, где осажденная пленка встречается с подложкой. Он по своей природе менее чист и электронно стабилен, чем термически выращенный интерфейс. По этой причине термический оксид является бескомпромиссным выбором для критического затворного диэлектрика в транзисторе.

Правильный выбор для вашей цели

Правильный процесс полностью определяется конкретными инженерными требованиями на каждом этапе изготовления.

- Если ваша основная цель — создание высокопроизводительного затворного диэлектрика для транзистора: Термическое окисление — единственный выбор из-за его превосходного интерфейса и качества пленки.

- Если ваша основная цель — осаждение изолирующего слоя между металлическими линиями: CVD — необходимый инструмент, так как он может осаждать SiO₂ или другие диэлектрики поверх различных материалов.

- Если ваша основная цель — создание твердой маски или окончательного пассивирующего слоя: CVD — ваш единственный вариант для осаждения необходимого материала, такого как нитрид кремния (Si₃N₄).

В конечном итоге, понимание фундаментального различия между выращиванием собственного слоя и осаждением чужеродного является ключом к освоению современного производства.

Сводная таблица:

| Характеристика | Химическое осаждение из газовой фазы (CVD) | Термическое окисление |

|---|---|---|

| Тип процесса | Осаждает новый материал на подложку | Выращивает материал из подложки |

| Разнообразие материалов | Высокое (SiO₂, Si₃N₄, поликремний, металлы) | Низкое (только диоксид кремния) |

| Совместимость с подложкой | Широкая (кремний, металлы, стекло, существующие слои) | Ограничено кремниевыми подложками |

| Температурный диапазон | Широкий (включая низкотемпературные варианты PECVD) | Высокий (900-1200°C) |

| Основное применение | Многослойные структуры, межсоединения, маски | Затворные диэлектрики, критически важные для интерфейса слои |

Нужны точные решения для тонких пленок для вашей лаборатории? KINTEK специализируется на передовом лабораторном оборудовании и расходных материалах для исследований и разработок в области полупроводников. Независимо от того, требуются ли вам системы CVD для универсального осаждения материалов или печи для окисления для высококачественного роста интерфейсов, наш опыт обеспечивает оптимальную производительность процесса. Свяжитесь с нашими экспертами сегодня, чтобы обсудить, как наши решения могут улучшить ваши производственные возможности и ускорить ваши исследования.

Визуальное руководство

Связанные товары

- Наклонная роторная установка для плазменно-усиленного химического осаждения из паровой фазы PECVD

- Оборудование системы HFCVD для нанесения наноалмазного покрытия на волочильные фильеры

- 915 МГц MPCVD Алмазная установка Микроволновая плазменная химическая осаждение из газовой фазы Система реактора

- Вакуумная печь горячего прессования для ламинирования и нагрева

- Раздельная трубчатая печь 1200℃ с кварцевой трубой, лабораторная трубчатая печь

Люди также спрашивают

- В чем разница между плазменным и термическим ХОН? Выберите правильный метод для вашей подложки

- Каковы технологические возможности систем ICPCVD? Достижение низкотемпературного осаждения пленок с низким уровнем повреждений при сверхнизких температурах

- Может ли плазменно-усиленное химическое осаждение из газовой фазы (PECVD) осаждать металлы? Почему PECVD редко используется для осаждения металлов

- Как системы PECVD улучшают DLC-покрытия на имплантатах? Объяснение превосходной долговечности и биосовместимости

- Каков процесс PECVD в полупроводниках? Обеспечение осаждения тонких пленок при низких температурах