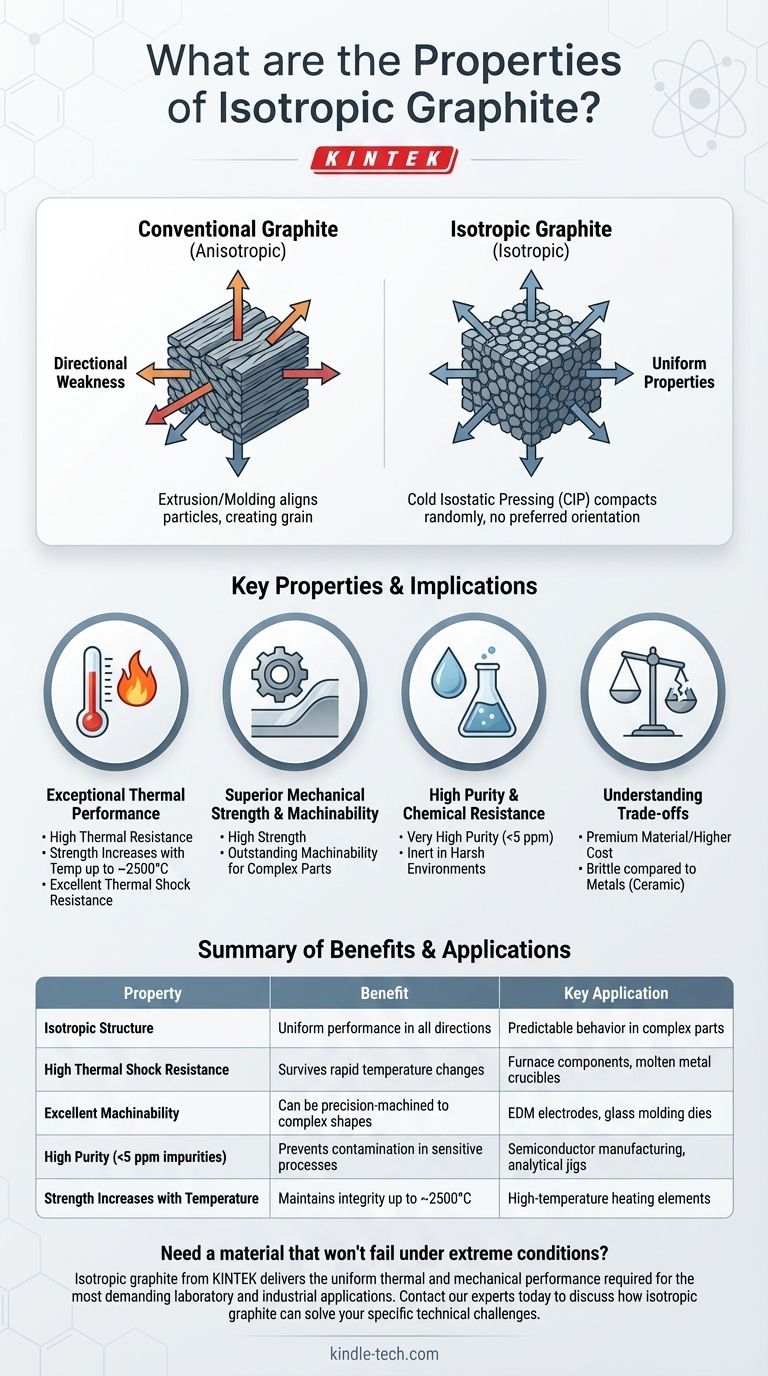

По сути, изотропный графит — это передовой, ультрамелкозернистый материал, определяемый его однородными свойствами во всех направлениях. Его ключевые характеристики включают исключительно высокую термическую и химическую стойкость, высокую прочность, которая увеличивается с температурой, отличную устойчивость к термическому шоку и способность к механической обработке для получения точных, сложных геометрических форм. Эта уникальная комбинация обусловлена его производственным процессом, известным как холодное изостатическое прессование (CIP).

Фундаментальное преимущество изотропного графита заключается не только в одном свойстве, но и в устранении направленной слабости. В отличие от стандартного графита, его однородная структура обеспечивает предсказуемую, высокоэффективную работу независимо от ориентации, что делает его надежным выбором для самых требовательных применений.

Что делает этот графит "изотропным"?

Чтобы понять ценность изотропного графита, вы должны сначала понять ограничения обычного графита, который обычно является анизотропным (его свойства варьируются в зависимости от направления).

Проблема со стандартным графитом

Большинство графитов формируется путем экструзии или формования. Эти процессы выравнивают частицы графита в определенном направлении, создавая зерно.

Такое выравнивание означает, что материал будет иметь различные значения теплопроводности, электрического сопротивления и механической прочности при измерении вдоль зерна по сравнению с измерением поперек него. Это может быть критической точкой отказа в условиях высоких нагрузок.

Решение с изостатическим прессованием

Изотропный графит производится по-другому. Смесь ультрамелких частиц графита и связующего помещается в гибкую форму и подвергается экстремальному, равномерному гидравлическому давлению со всех сторон в холодно-изостатическом прессе (CIP).

Этот процесс уплотняет частицы случайным образом, без предпочтительной ориентации. Полученный твердый блок, или заготовка, имеет гомогенную, ненаправленную и очень мелкозернистую внутреннюю структуру.

Ключевые свойства и их последствия

Однородная, мелкозернистая структура, созданная изостатическим прессованием, напрямую приводит к набору превосходных и высокопредсказуемых свойств.

Исключительные термические характеристики

Изотропный графит превосходно работает в высокотемпературных условиях. Он обладает чрезвычайно высокой термостойкостью и, что уникально, его механическая прочность увеличивается с температурой примерно до 2500°C.

Кроме того, сочетание высокой теплопроводности и низкого термического расширения обеспечивает ему отличную устойчивость к термическому шоку. Это позволяет ему выдерживать быстрые изменения температуры, которые разрушили бы большинство других материалов.

Превосходная механическая прочность и обрабатываемость

Благодаря своей ультрамелкозернистой структуре и отсутствию направленной слабости, изотропный графит обладает высокой механической прочностью для керамического материала.

Эта структура также обеспечивает выдающуюся обрабатываемость. Из него можно изготавливать сложные, замысловатые детали с четкими деталями и чрезвычайно гладкой поверхностью, что невозможно с более грубыми, анизотропными марками графита.

Высокая чистота и химическая стойкость

Производственный процесс позволяет получать изотропный графит очень высокой чистоты, часто с уровнем примесей ниже 5 частей на миллион (ppm). Это критически важно для таких применений, как производство полупроводников, где загрязнение может испортить целые производственные партии.

Он также наследует естественную высокую химическую стойкость и инертность графита, что делает его пригодным для использования с агрессивными веществами и в суровых химических средах.

Понимание компромиссов

Хотя изотропный графит предлагает превосходные характеристики, он не является выбором по умолчанию для каждого применения. Понимание его ограничений является ключом к принятию обоснованного инженерного решения.

Соображения стоимости

Изостатическое прессование — это более сложный и дорогостоящий производственный процесс, чем простая экструзия. Следовательно, изотропный графит является материалом премиум-класса со значительно более высокой стоимостью, чем стандартные марки графита. Его использование оправдано только тогда, когда его уникальные свойства действительно необходимы.

Хрупкость по сравнению с металлами

Хотя он очень прочен для графита, и его прочность увеличивается с нагревом, он остается керамическим материалом. Ему не хватает пластичности металлов, и он разрушается без значительной пластической деформации. Он не является подходящей заменой металлическим сплавам в приложениях, требующих высокой вязкости разрушения или ударопрочности при комнатной температуре.

Специфика применения

Использование изотропного графита для простого нагревательного элемента в низкокачественной печи было бы излишним. Он специально разработан для применений, где механические напряжения, требования к точности или требования к термическому циклу превышают возможности обычных мелкозернистых графитов.

Правильный выбор для вашего применения

Выбор правильного материала требует сопоставления его свойств с вашей основной инженерной целью.

- Если ваша основная задача — высокотемпературная стабильность и термостойкость: Изотропный графит идеально подходит для компонентов печей, тиглей для расплавленного металла и форм для непрерывного литья благодаря его способности выдерживать экстремальные термические циклы.

- Если ваша основная задача — прецизионная обработка и гладкие поверхности: Его однородная, мелкозернистая структура делает его окончательным выбором для электродов электроэрозионной обработки (ЭЭО), форм для формования стекла и полупроводниковых приспособлений.

- Если ваша основная задача — чистота материала: Его доступность в сверхчистых марках является обязательной для применения в полупроводниковой, ядерной и аналитической отраслях, где контроль загрязнений имеет первостепенное значение.

Понимая эти явные преимущества, вы можете с уверенностью определить, является ли изотропный графит оптимальным решением для вашей конкретной технической задачи.

Сводная таблица:

| Свойство | Преимущество | Ключевое применение |

|---|---|---|

| Изотропная структура | Однородная производительность во всех направлениях | Предсказуемое поведение в сложных деталях |

| Высокая термостойкость | Выдерживает быстрые изменения температуры | Компоненты печей, тигли для расплавленного металла |

| Отличная обрабатываемость | Может быть точно обработан до сложных форм | Электроды ЭЭО, формы для формования стекла |

| Высокая чистота (<5 ppm примесей) | Предотвращает загрязнение в чувствительных процессах | Производство полупроводников, аналитические приспособления |

| Прочность увеличивается с температурой | Сохраняет целостность до ~2500°C | Высокотемпературные нагревательные элементы |

Нужен материал, который не подведет в экстремальных условиях?

Изотропный графит от KINTEK обеспечивает однородные термические и механические характеристики, необходимые для самых требовательных лабораторных и промышленных применений. Независимо от того, разрабатываете ли вы прецизионные компоненты для производства полупроводников, высокотемпературные детали печей или сложные электроды ЭЭО, наш опыт в области передовых лабораторных материалов гарантирует, что вы получите решение, адаптированное к вашим точным потребностям.

Свяжитесь с нашими экспертами сегодня, чтобы обсудить, как изотропный графит может решить ваши конкретные технические задачи.

Визуальное руководство

Связанные товары

- Углеграфитовая пластина, изготовленная методом изостатического прессования

- Графитовая вакуумная печь для графитации пленки с высокой теплопроводностью

- Графитовая вакуумная печь для экспериментальной графитизации на IGBT-транзисторах

- Вертикальная высокотемпературная вакуумная графитизационная печь

- Большая вертикальная графитировочная печь с вакуумом

Люди также спрашивают

- Является ли пиролиз самоподдерживающимся процессом? Достижение энергетической независимости в переработке отходов

- Какова максимальная температура для всех металлических хотэндов? Ограничение не в металле, а в электронике.

- Почему биоуголь вызывает споры? Сочетание климатических перспектив с реальными рисками

- Что такое процесс напыления для осаждения тонких пленок? Руководство по прецизионному нанесению тонких пленок

- Какое биотопливо самое дешевое? Откройте для себя истинную стоимость, выходящую за рамки ценника

- Каковы некоторые недостатки порошковой металлургии? Ограничения по размеру, прочности и сложности

- От чего зависит размер выборки? Освойте 3 ключевых фактора для точного исследования

- Что является продуктом физического осаждения из паровой фазы? Высокоэффективное тонкопленочное покрытие