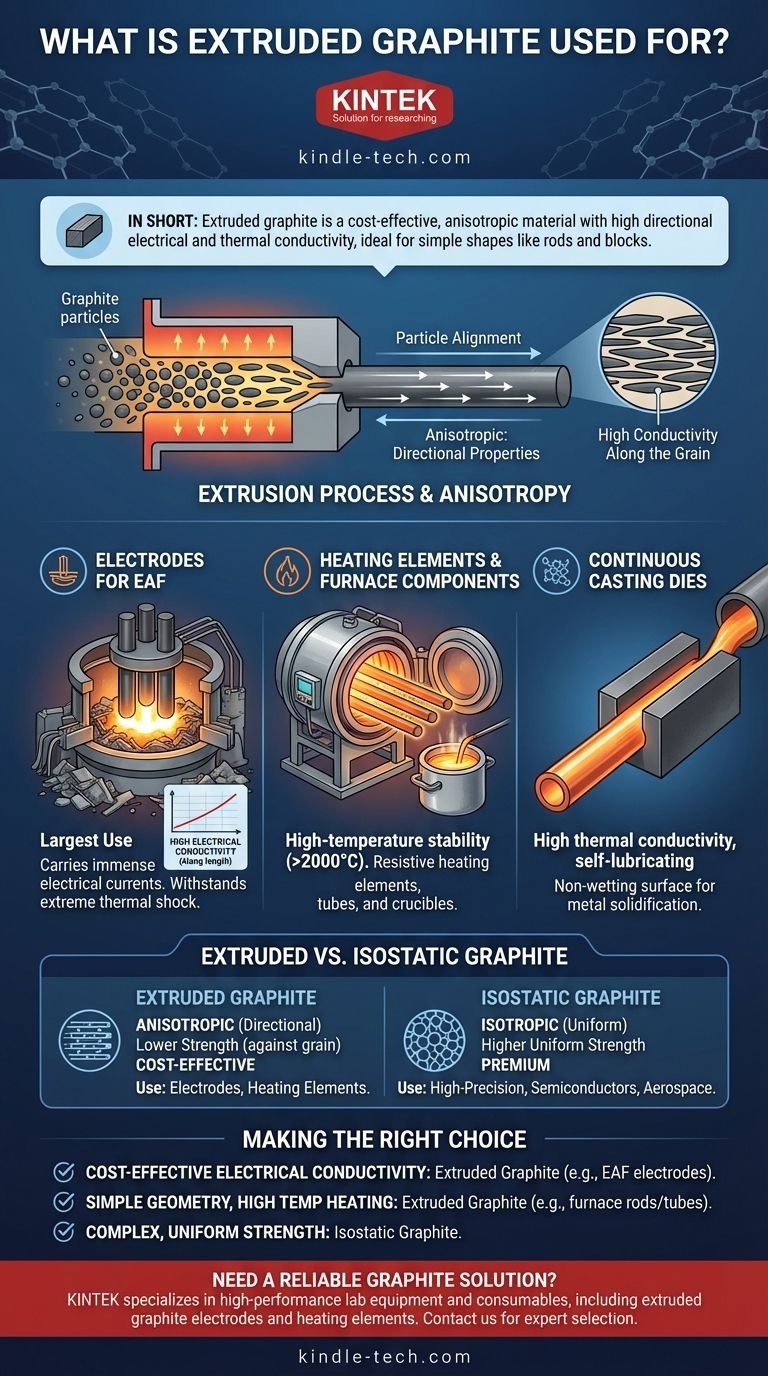

Коротко говоря, экструдированный графит в основном используется в тех областях, где критически важны экономичность и высокая электрическая или тепловая проводимость в определенном направлении. Наиболее распространенные области его применения — это электроды в электродуговых печах для переработки стали, нагревательные элементы в высокотемпературных промышленных печах и тигли для плавки металлов.

Основной принцип, который следует понять, заключается в том, что процесс экструзии выравнивает частицы графита, создавая материал с превосходными направленными свойствами. Это делает его идеальным, экономичным выбором для простых форм, таких как стержни и блоки, но менее подходящим для сложных компонентов, требующих равномерной прочности во всех направлениях.

Определяющие свойства экструдированного графита

Чтобы понять его применение, мы должны сначала понять, как производится экструдированный графит и какие характеристики являются результатом этого процесса. Это не универсальный материал; это специализированный инструмент для конкретных задач.

Процесс экструзии и анизотропия

Экструдированный графит производится путем смешивания нефтяного кокса и связующего, нагревания его и продавливания через фильеру для придания формы, обычно стержня или блока.

Этот процесс заставляет плоские, пластинчатые частицы графита выравниваться параллельно направлению экструзии. Такое выравнивание создает анизотропный материал, что означает, что его свойства различаются при измерении вдоль волокон и поперек волокон.

Направленная проводимость

Основным следствием этой анизотропии является превосходная электрическая и тепловая проводимость вдоль длины экструдированной формы (вдоль волокон). Выровненные частицы создают эффективный путь для прохождения электричества и тепла.

Проводимость значительно ниже при измерении поперек волокон, что является важным фактором в инженерном проектировании.

Экономичность

По сравнению с другими методами производства синтетического графита, такими как изостатическое прессование, экструзия является более экономичным, крупносерийным производственным процессом. Это делает его выбором по умолчанию для применений, которые потребляют большое количество графита.

Подробное описание основных применений

Уникальное сочетание проводимости, стабильности при высоких температурах и экономичности делает экструдированный графит незаменимым в нескольких ключевых отраслях промышленности.

Электроды для электродуговых печей (ЭДП)

Это самое крупное единичное применение экструдированного графита. Массивные графитовые электроды, часто диаметром более двух футов, используются для подачи огромных электрических токов в электродуговые печи.

Ток плавит стальной лом в рамках процесса переработки. Экструдированный графит — единственный материал, который может обеспечить требуемую электрическую проводимость и выдерживать экстремальный термический удар этой среды при приемлемой стоимости.

Нагревательные элементы и компоненты печей

В вакуумных или инертных печах, работающих при очень высоких температурах, экструдированные графитовые стержни и трубки часто используются в качестве резистивных нагревательных элементов.

Их способность сохранять прочность и проводить электричество при температурах значительно выше 2000°C имеет решающее значение. Из них также изготавливают тигли для металлургических процессов, связанных с плавкой цветных металлов.

Изложницы для непрерывного литья

При производстве таких металлов, как медь и алюминий, расплавленный металл часто протягивается через фильеру для формирования стержней, труб и других форм.

Экструдированный графит является отличным материалом для этих изложниц благодаря его высокой теплопроводности (которая способствует затвердеванию металла), самосмазывающимся свойствам и тому факту, что большинство расплавленных металлов не смачивают его поверхность.

Понимание компромиссов: экструдированный против изостатического графита

Выбор правильного типа графита имеет решающее значение. Наиболее распространенной альтернативой экструдированному графиту является изостатический графит, который служит совершенно другой цели.

Анизотропия против изотропии

Как мы уже говорили, экструдированный графит анизотропен. Его прочность и проводимость направлены.

Изостатический графит изготавливается путем прессования графитового порошка со всех сторон одновременно, что приводит к случайной ориентации частиц. Это делает его изотропным, что означает, что его свойства однородны и постоянны во всех направлениях.

Прочность и структура зерна

Изостатический графит имеет гораздо более тонкую зернистую структуру и более высокую механическую прочность. Его однородность делает его идеальным для обработки сложных, высокоточных компонентов, которые не могут иметь слабых мест.

Экструдированный графит имеет более крупную зернистую структуру и более низкую механическую прочность, особенно поперек волокон. Он не подходит для сложных конструкционных деталей, испытывающих разнонаправленные нагрузки.

Стоимость и производительность

Это существенный компромисс. Экструдированный графит — это экономичная рабочая лошадка. Изостатический графит — это высококачественный, высокопроизводительный материал, используемый в требовательных, передовых областях применения, таких как производство полупроводников, ядерные реакторы и аэрокосмические компоненты.

Правильный выбор для вашей цели

Конкретные требования вашего приложения к производительности, геометрии и стоимости определят, какой материал подходит.

- Если ваша основная цель — экономичная электропроводность для крупномасштабных процессов: Экструдированный графит является отраслевым стандартом для таких применений, как электроды электродуговых печей.

- Если ваша основная цель — высокотемпературные нагревательные элементы с простой геометрией: Экструдированный графит предлагает лучший баланс производительности и стоимости для компонентов печей, таких как стержни и трубки.

- Если ваша основная цель — сложные компоненты, требующие равномерной прочности и мелких деталей: Вы должны выбрать более высококачественный изотропный материал, такой как изостатический графит.

В конечном итоге, выбор правильного материала начинается с понимания того, что не весь графит одинаков.

Сводная таблица:

| Свойство | Экструдированный графит | Изостатический графит |

|---|---|---|

| Структура | Анизотропная (направленная) | Изотропная (однородная) |

| Основное применение | Электроды, нагревательные элементы, тигли | Высокоточные компоненты, полупроводники |

| Стоимость | Экономичный | Премиум |

| Прочность | Направленная, ниже поперек волокон | Высокая, равномерная во всех направлениях |

Нужно надежное графитовое решение для вашего промышленного или лабораторного применения? KINTEK специализируется на высокопроизводительном лабораторном оборудовании и расходных материалах, включая компоненты из экструдированного графита, такие как электроды и нагревательные элементы. Наши эксперты помогут вам выбрать правильный материал для экономичной проводимости и стабильности при высоких температурах. Свяжитесь с нами сегодня, чтобы обсудить ваши конкретные потребности и повысить эффективность вашего процесса с помощью проверенных решений KINTEK.

Визуальное руководство

Связанные товары

- Горизонтальная высокотемпературная графитизационная печь с графитовым нагревом

- Графитовая вакуумная печь с нижним выгрузкой для графитации углеродных материалов

- Графитовый тигель высокой чистоты для испарения

- Муфельная печь для лаборатории 1200℃

- Муфельная печь 1700℃ для лаборатории

Люди также спрашивают

- Каковы преимущества спеченного металла? Создание прочных, сложных деталей с экономической эффективностью

- Каковы два метода контроля коррозии? Овладейте стратегиями защиты металлов

- Почему запрограммированный контроль температуры имеет решающее значение для катализаторов Ce-TiOx/npAu? Достижение точности при активации катализатора

- Что такое метод вакуумной сублимации? Руководство по очистке материалов высокой чистоты

- Что такое терпенный дистиллят? Руководство по высокоэффективному ароматизированному маслу каннабиса

- Какие технические проблемы решают интегрированные мембранные технологии в электрокаталитических реакторах, используемых для очистки сточных вод?

- Есть ли способ ламинировать без ламинатора? Да, с помощью этих простых самодельных методов.

- Можно ли рафинировать пиролизное масло? Получение высокоценного топлива из биосырья