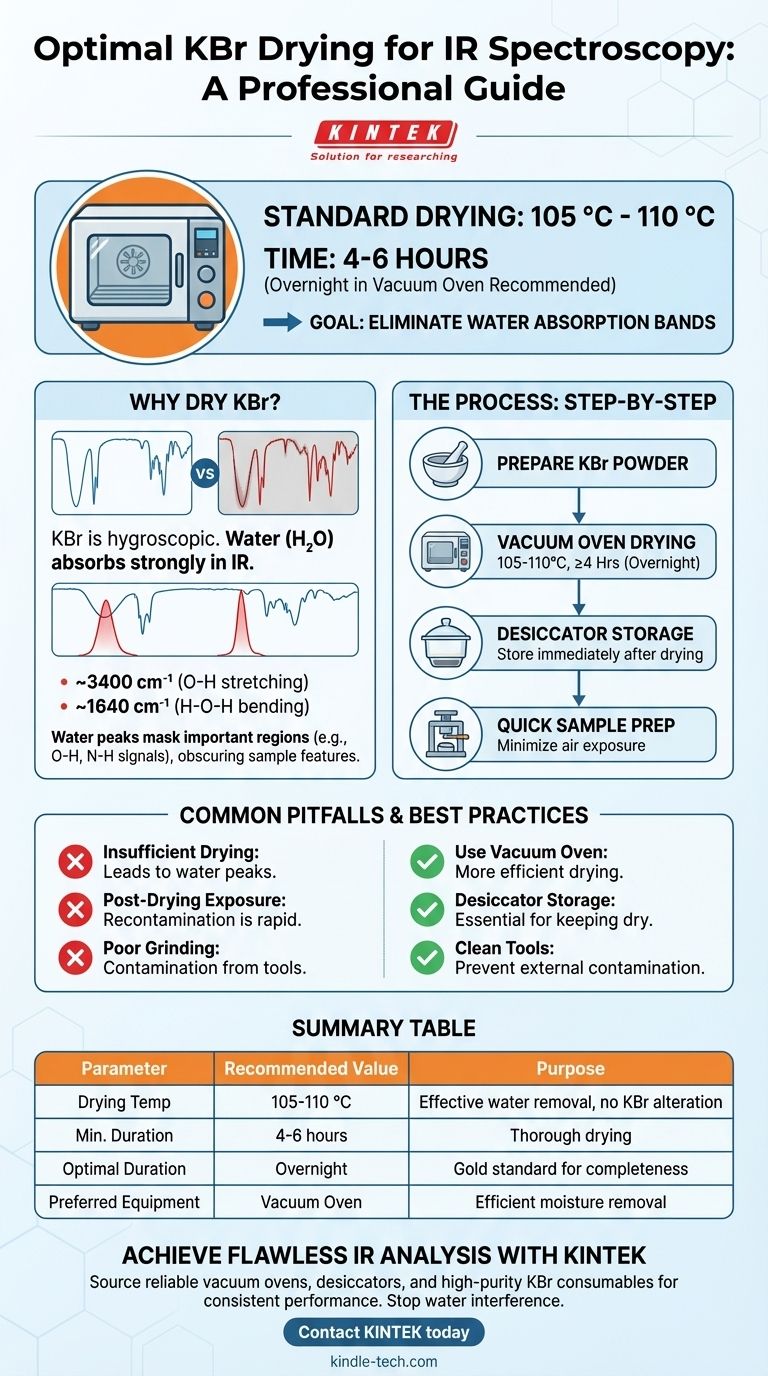

Для достижения оптимальных результатов в ИК-спектроскопии стандартной и самой безопасной температурой для сушки бромида калия (KBr) является температура от 105 °C до 110 °C. Этот процесс следует проводить не менее 4 часов, хотя самой распространенной лабораторной практикой является сушка в вакуумном шкафу в течение ночи, чтобы гарантировать удаление всей адсорбированной воды.

Основная цель сушки KBr — устранить сильные, мешающие инфракрасному поглощению полосы воды. Неправильная сушка KBr приведет к появлению значительных артефактов в вашем спектре, что может маскировать истинные спектральные характеристики вашего образца и привести к неверной интерпретации данных.

Почему сушка KBr критически важна для ИК-анализа

Бромид калия является наиболее распространенным матричным материалом для ИК-спектроскопии твердых образцов, поскольку он прозрачен для инфракрасного излучения в широком диапазоне. Однако его основным недостатком является гигроскопичность, то есть он легко поглощает влагу из атмосферы.

Проблема загрязнения водой

Вода (H₂O) является очень сильным поглотителем инфракрасного излучения. Даже следовые количества влаги в вашем KBr создадут две отчетливые, характерные полосы поглощения в вашем спектре:

- Очень широкий, сильный пик около 3400 см⁻¹, обусловленный валентными колебаниями O-H.

- Узкий пик средней интенсивности около 1640 см⁻¹, обусловленный колебаниями изгиба H-O-H.

Влияние на качество спектра

Эти пики воды могут полностью замаскировать важные области спектра. Например, широкий пик при 3400 см⁻¹ может легко скрыть валентные колебания N-H аминов и амидов или сигналы O-H спиртов и карбоновых кислот в вашем реальном образце, делая анализ невозможным.

Стандартный протокол сушки

Достижение матрицы KBr, свободной от влаги, несложно, если следовать последовательному протоколу. Ключ заключается в балансе температуры и времени для удаления воды, не изменяя при этом сам KBr.

Рекомендуемая температура и продолжительность

Идеальный диапазон температур составляет 105-110 °C. Это безопасно выше точки кипения воды (100 °C), что обеспечивает эффективное удаление, но значительно ниже точки плавления KBr (~734 °C), что исключает риск спекания или плавления порошка.

Рекомендуется сушить не менее 4-6 часов, при этом сушка в течение ночи является золотым стандартом для обеспечения полной сухости.

Роль вакуумного шкафа

Использование вакуумного шкафа является предпочтительным. Вакуум снижает эффективную температуру кипения воды и активно удаляет пары влаги из порошка KBr, что приводит к более тщательному и эффективному процессу сушки по сравнению со стандартной конвекционной печью.

Распространенные ошибки и лучшие практики

Просто сушка KBr — это только половина дела. Правильное обращение после сушки имеет решающее значение для предотвращения повторного загрязнения.

Недостаточная сушка

Если вы сократите время сушки или используете слишком низкую температуру, вы не удалите всю адсорбированную воду. Вы немедленно увидите характерные пики воды в вашем фоновом сканировании или спектре образца.

Загрязнение после сушки

После сушки KBr становится чрезвычайно гигроскопичным и немедленно начинает поглощать атмосферную влагу.

- Всегда храните высушенный порошок KBr в герметичном контейнере внутри эксикатора.

- При приготовлении таблетки образца работайте как можно быстрее и эффективнее, чтобы минимизировать время воздействия KBr на окружающий воздух.

Неправильная техника измельчения

При измельчении образца с высушенным KBr убедитесь, что и ступка, и пестик идеально чистые и сухие. Любая остаточная влага или чистящий растворитель на ваших инструментах загрязнят смесь, которую вы так усердно готовили.

Сделайте правильный выбор для вашей цели

Ваша аналитическая цель определяет, насколько тщательно вы должны следовать этой процедуре.

- Если ваше основное внимание уделяется «отпечатку пальца» (ниже 1500 см⁻¹): Хотя это по-прежнему важно, незначительное загрязнение влагой с меньшей вероятностью будет напрямую влиять на валентные колебания связей C-C, C-O или C-X.

- Если ваше основное внимание уделяется идентификации функциональных групп O-H или N-H: Тщательная сушка и обращение являются обязательными. Даже следовые сигналы воды могут создать ложноположительные результаты или замаскировать тонкие особенности вашего аналита.

- Если вы проводите количественный анализ: Абсолютно чистый, сухой и воспроизводимый фон имеет решающее значение, что делает полный ночной протокол с вакуумным шкафом единственным надежным вариантом.

В конечном счете, правильная подготовка KBr является основой надежных и воспроизводимых спектроскопических результатов.

Сводная таблица:

| Параметр | Рекомендуемое значение | Назначение |

|---|---|---|

| Температура сушки | 105 - 110 °C | Эффективно удаляет воду, не изменяя KBr. |

| Минимальная продолжительность | 4-6 часов | Обеспечивает тщательную сушку. |

| Оптимальная продолжительность | В течение ночи | Золотой стандарт для полного удаления влаги. |

| Предпочтительное оборудование | Вакуумный шкаф | Снижает температуру кипения воды для более эффективной сушки. |

Достигните безупречного ИК-анализа с KINTEK

Устранение влияния влаги имеет решающее значение для точной ИК-спектроскопии. Правильно высушенный KBr — это основа надежных результатов. KINTEK специализируется на предоставлении высококачественного лабораторного оборудования и расходных материалов, необходимых для совершенствования подготовки ваших образцов.

Мы можем помочь вам:

- Найти надежные вакуумные шкафы для эффективной сушки KBr.

- Найти подходящие эксикаторы и решения для хранения, чтобы ваш высушенный KBr оставался без загрязнений.

- Получить доступ к высокочистым порошкам KBr и расходным материалам для стабильной работы.

Перестаньте позволять пикам воды затенять ваши данные. Позвольте нашим экспертам поддержать успех вашей лаборатории.

Свяжитесь с KINTEK сегодня, чтобы обсудить ваши конкретные потребности в лабораторном оборудовании!

Визуальное руководство

Связанные товары

- Лабораторная научная электрическая конвекционная сушильная печь

- Муфельная печь для лаборатории 1200℃

- Графитировочная печь для вакуумного графитирования материалов отрицательного электрода

- Горизонтальная высокотемпературная графитизационная печь с графитовым нагревом

- Большая вертикальная графитировочная печь с вакуумом

Люди также спрашивают

- Каковы компоненты пленочного испарителя? Ключевые части для эффективной низкотемпературной дистилляции

- Что такое метод физического осаждения из паровой фазы для синтеза наноматериалов? Достижение точности на атомном уровне

- Какие печи используются в металлургии? Руководство по плавке, легированию и термообработке

- Какая рекомендуемая температура хранения для сыворотки человека? Сохраняйте целостность образца для получения надежных результатов

- Каковы преимущества использования биомассы? Достижение решений в области возобновляемой энергетики и преобразования отходов в энергию

- Можно ли повторно нагревать паяное соединение? Руководство по ремонту, разборке и процессам после пайки

- Какова производительность проходной печи? Откройте для себя высокопроизводительное спекание от 50 до 1000 кг/день

- Можно ли испарять дистиллят ТГК? Полное руководство по вейпингу мощных концентратов