По своей сути, гидравлический горячий пресс работает за счет сочетания двух фундаментальных принципов: огромной, контролируемой силы, генерируемой гидравлической системой, и тепловой энергии от нагретых плит. Этот синергетический эффект позволяет машине точно прессовать, склеивать или формовать материалы. Гидравлическая система использует несжимаемую жидкость, как правило, масло, для многократного увеличения небольшого начального усилия до огромного, равномерного давления, в то время как нагретые плиты (подогреватели) размягчают заготовку или активируют клеи для достижения желаемого результата.

Эффективность машины проистекает из простого физического принципа — закона Паскаля, — усиленного современной автоматизацией. Он преобразует мощность небольшого насоса в тонны равномерного усилия, в то время как сложная система управления регулирует температуру и давление для обеспечения стабильных, высококачественных результатов.

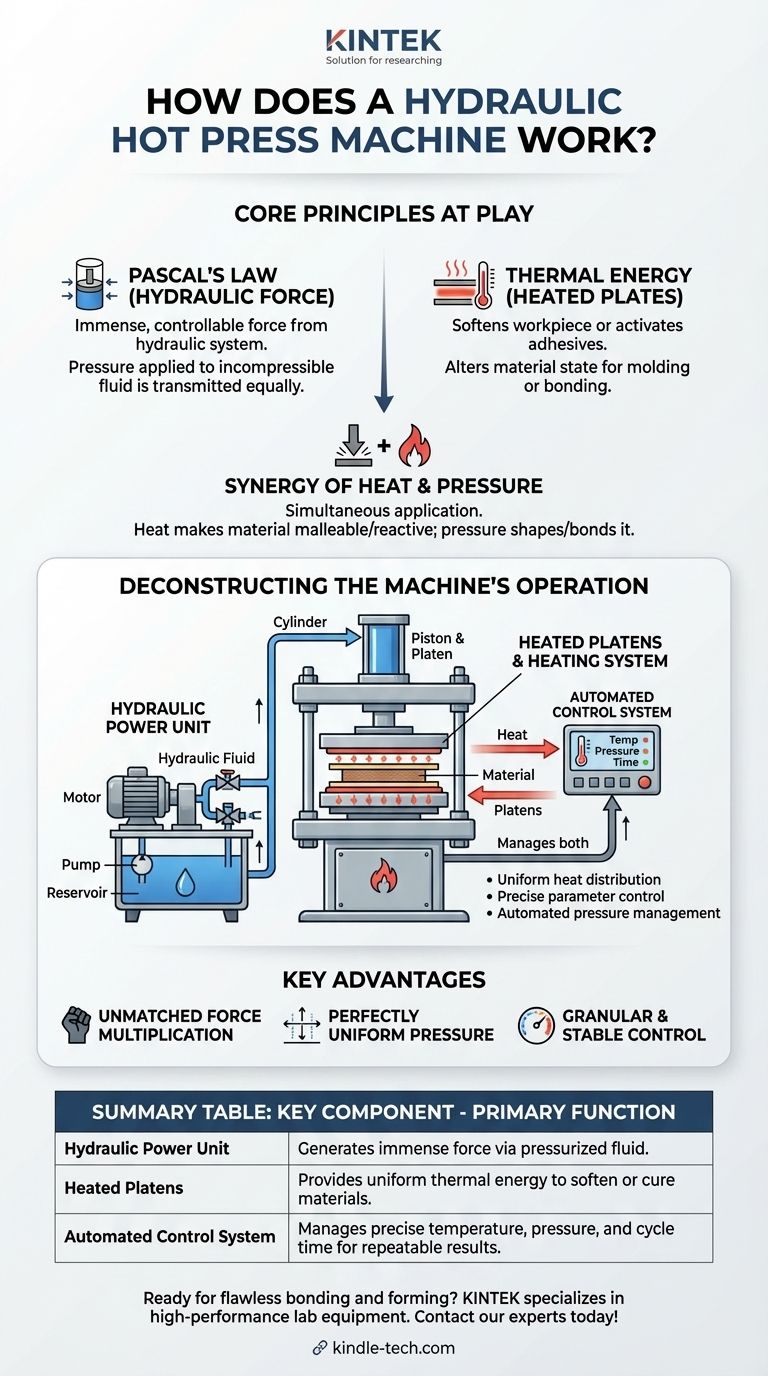

Основные действующие принципы

Чтобы по-настоящему понять работу машины, необходимо сначала уловить два научных понятия, которые обеспечивают ее функционирование. Эти принципы работают в тандеме для манипулирования материалами с высокой степенью точности.

Закон Паскаля: Двигатель силы

Слово «гидравлический» в названии относится к источнику его мощности, который регулируется законом Паскаля. Этот закон гласит, что давление, приложенное к замкнутой несжимаемой жидкости, передается одинаково по всей этой жидкости.

Гидравлический пресс использует это, используя насос для создания давления на гидравлическое масло в небольшом цилиндре. Затем это давление передается на гораздо больший поршень, что значительно увеличивает начальное усилие. Это позволяет относительно небольшому двигателю генерировать огромное и в высшей степени контролируемое усилие прессования.

Тепловая энергия: Катализатор изменений

Аспект «горячий пресс» относится к нагревательным плитам машины. Эти большие плоские плиты обычно нагреваются внутренними электрическими элементами или циркулирующим теплоносителем.

Цель нагрева — изменить состояние заготовки. Он может размягчать пластики или композиты, делая их податливыми для формования, или он может отверждать термореактивные смолы и активировать клеи для постоянного склеивания, например, при ламинировании древесного шпона.

Синергия тепла и давления

Ни тепло, ни давление по отдельности не были бы столь эффективными. Машина применяет их одновременно для конкретной цели.

Тепло делает материал податливым или химически активным. Огромное, равномерное давление затем заставляет материал принять новую форму или обеспечивает тесный контакт между слоями без пузырей для идеального склеивания.

Разбор работы машины

Гидравлический горячий пресс — это интегрированная система, в которой каждый компонент играет решающую роль в достижении точного и повторяемого процесса.

Гидравлический силовой агрегат

Это сердце машины. Он состоит из двигателя, насоса, резервуара для гидравлической жидкости и управляющих клапанов. Насос нагнетает жидкость в основной гидравлический цилиндр, приводя в движение поршень и прикрепленную к нему плиту.

Нагревательные плиты и система нагрева

Плиты — это рабочие поверхности, которые передают тепло и усилие материалу. Эффективная система нагрева, часто использующая ряд точно расположенных нагревательных трубок или картриджей, имеет решающее значение для обеспечения быстрого и, что наиболее важно, равномерного распределения тепла по всей поверхности.

Автоматизированная система управления

Современные машины управляются с помощью передовой панели управления. Эта система позволяет оператору устанавливать точные параметры температуры, давления и времени цикла прессования.

Критически важно, что она автоматизирует процесс нагнетания давления, удержания давления и пополнения давления. Это гарантирует, что заготовка подвергается равномерному давлению на протяжении всего цикла, что необходимо для предотвращения дефектов и обеспечения качества продукции.

Ключевые преимущества гидравлической конструкции

Выбор гидравлической системы является преднамеренным, поскольку она предлагает явные преимущества перед механическими или пневматическими аналогами, особенно когда задействовано тепло.

Непревзойденное умножение силы

Как объясняет закон Паскаля, гидравлические системы обеспечивают наиболее эффективный способ генерации огромных усилий, необходимых для промышленных процессов прессования. Это достигается с помощью относительно компактных и энергоэффективных компонентов.

Идеально равномерное давление

Ключевое преимущество использования жидкости для передачи силы заключается в том, что она равномерно распределяет давление по всей поверхности поршня. Эта однородность передается на плиту и заготовку, устраняя слабые места и обеспечивая стабильное качество, что критически важно для ламинирования и формования.

Гранулированное и стабильное управление

Гидравлические системы обеспечивают точный и стабильный контроль над приложенной силой. Система может удерживать определенное давление в течение длительного периода без колебаний, а система управления может вносить микрокорректировки по мере необходимости. Такой уровень контроля жизненно важен при работе с чувствительными материалами.

Применение этого к вашим целям

Понимание того, как работает машина, позволяет вам использовать ее возможности для достижения конкретных производственных результатов. Ваш фокус будет определять, какой аспект ее работы является наиболее важным.

- Если ваша основная цель — склеивание материалов (например, ламинирование фанеры): Ключевым моментом является способность системы применять равномерное тепло для активации клея и равномерное давление для обеспечения безупречного склеивания без пустот на большой площади.

- Если ваша основная цель — формование материалов (например, формование композитов): Критической функцией является точный контроль температуры для достижения пластичности материала в сочетании с огромной гидравлической силой, необходимой для прессования материала в сложную форму с идеальной точностью.

- Если ваша основная цель — стабильное качество продукции: Самой важной особенностью является автоматизированная система управления, которая гарантирует, что каждый цикл имеет один и тот же профиль температуры и давления, обеспечивая повторяемые результаты с минимальным вмешательством оператора.

Освоив взаимодействие гидравлической силы и тепловой энергии, горячий пресс обеспечивает непревзойденный контроль и точность в современном производстве.

Сводная таблица:

| Ключевой компонент | Основная функция |

|---|---|

| Гидравлический силовой агрегат | Генерирует огромное, контролируемое усилие с помощью жидкости под давлением. |

| Нагревательные плиты | Обеспечивает равномерную тепловую энергию для размягчения или отверждения материалов. |

| Автоматизированная система управления | Управляет точной температурой, давлением и временем цикла для повторяемых результатов. |

Готовы добиться безупречного склеивания и формования материалов в вашей лаборатории? KINTEK специализируется на высокопроизводительном лабораторном оборудовании, включая гидравлические горячие прессы, разработанные для обеспечения точности и надежности. Наши машины обеспечивают равномерный нагрев и давление, необходимые для ваших проектов. Свяжитесь с нашими экспертами сегодня, чтобы найти идеальное решение для нужд вашей лаборатории!

Визуальное руководство

Связанные товары

- Ручной гидравлический пресс с нагревательными плитами для лабораторного горячего прессования

- Автоматический гидравлический пресс с подогревом и нагревательными плитами для лабораторного горячего прессования 25Т 30Т 50Т

- Ручной высокотемпературный гидравлический пресс с нагревательными плитами для лаборатории

- Гидравлический пресс с подогревом и встроенными ручными нагревательными плитами для лабораторного использования

- Двухплитная нагревательная пресс-форма для лаборатории

Люди также спрашивают

- Какова температура горячей ковки? Достижение превосходной прочности и формуемости

- Каково применение машины горячего прессования? Достижение превосходного соединения и формования материалов

- Что такое хороший мини-термопресс? Достигайте профессиональных результатов на мелких, сложных предметах

- Какова роль лабораторного обогреваемого гидравлического пресса в изготовлении МЭБ? Оптимизация производительности топливных элементов

- Что такое процесс горячего прессования полимеров? Достижение максимальной плотности и прочности для критически важных деталей

- Какие технические условия обеспечивает нагретый гидравлический пресс для батарей PEO? Оптимизация твердотельных интерфейсов

- Каковы преимущества использования горячего прессования по сравнению с холодным прессованием для композитных катодов LiMOCl4? Повышение эффективности аккумулятора

- Как лабораторный нагревательно-перемешивающий прибор помогает загружать частицы платины (Pt) на углеродные носители методом восстановления муравьиной кислотой?