Для общей безопасности и защиты оборудования следует подождать, пока муфельная печь остынет до температуры ниже 200°C (392°F), прежде чем открывать дверцу. Хотя специализированные высокотемпературные процедуры могут требовать доступа к печи при температурах до 600°C, это является исключением для обученного персонала со специальным оборудованием и не является стандартной практикой для рутинной эксплуатации.

«Безопасная» температура открытия не является единым числом, а полностью определяется вашей задачей. Путать требования к специализированной горячей обработке с рутинным извлечением образцов — это критическая ошибка безопасности. Для большинства пользователей терпение имеет первостепенное значение; ожидание значительного охлаждения печи предотвращает травмы персонала и повреждение оборудования от термического шока.

Почему «безопасная температура» зависит от задачи

Правильная температура для открытия муфельной печи зависит от того, что вы пытаетесь сделать. Риски и требования к обращению с материалом при определенной технологической температуре принципиально отличаются от простого извлечения охлажденного образца.

Исключение для высоких температур: горячая обработка

Некоторые металлургические или керамические процессы, такие как закалка или ковка, требуют извлечения материалов из печи, пока они еще чрезвычайно горячие.

Для этих конкретных задач оператор может открыть дверцу, когда печь находится при температуре 600°C или даже выше. Это сложная процедура, которая абсолютно требует специализированных инструментов, таких как длинные щипцы, карбидокремниевые подовые плиты для защиты дна печи, и обширных средств индивидуальной защиты (СИЗ), включая полнолицевые щитки и высокотемпературные перчатки.

Общее правило: рутинное охлаждение и извлечение

Для всех других стандартных применений основными целями являются защита оператора от экстремального тепла и предотвращение повреждения печи или ее содержимого.

Открытие печи при температуре выше 200°C создает значительные риски для безопасности и подвергает оборудование потенциальному повреждению от термического шока.

Два основных риска открытия печи, когда она слишком горячая

Спешка с открытием муфельной печи влечет за собой две основные опасности, которых полностью избегает терпеливый, методичный подход.

Риск 1: Серьезные травмы персонала

В момент открытия дверцы высвобождается поток перегретого воздуха. Этот конвективный тепловой поток может мгновенно вызвать серьезные ожоги незащищенной кожи и глаз.

Кроме того, лучистое тепло от стенок печи и ее содержимого может быть достаточно интенсивным, чтобы вызвать серьезные травмы даже на расстоянии.

Риск 2: Повреждение от термического шока

Термический шок возникает, когда материал испытывает быстрое, неравномерное изменение температуры, что приводит к его растрескиванию или разрушению.

Когда вы открываете горячую печь, внутрь устремляется холодный окружающий воздух. Это может привести к катастрофическому разрушению керамической изоляции или тиглей внутри, что повлечет за собой дорогостоящий и трудоемкий ремонт. Тот же шок может также испортить образец или материал, который вы обрабатывали.

Понимание компромиссов

Единственная «выгода» от раннего открытия печи — это экономия небольшого количества времени. Это удобство сопряжено со значительными рисками.

Миф о скорости

В профессиональной или исследовательской среде время, сэкономленное за счет преждевременного открытия, ничтожно по сравнению с потенциальной стоимостью неудачного процесса, поврежденной печи или инцидента, связанного с безопасностью.

Ценность терпения

Естественное охлаждение печи в соответствии с запрограммированным снижением температуры или простое отключение питания гарантирует, что изменение температуры будет постепенным и равномерным.

Это защищает хрупкие керамические компоненты печи и сохраняет целостность материалов внутри. Это основа воспроизводимой, надежной термической обработки.

Правильный выбор для вашей цели

Всегда оценивайте свою конкретную задачу и ставьте безопасность и сохранность оборудования превыше всего.

- Если ваша основная задача — специализированная горячая обработка (например, закалка стали): Вы будете работать при высоких температурах, продиктованных вашим процессом, но это требует экспертной подготовки и специализированного оборудования для безопасности и обращения.

- Если ваша основная задача — общая безопасность и извлечение готового образца: Вы должны дождаться, пока печь остынет до температуры ниже 200°C, и всегда использовать соответствующие СИЗ (термостойкие перчатки, защитный щиток для лица) даже при этой более низкой температуре.

- Если вы когда-либо сомневаетесь в температуре: Самый безопасный и профессиональный выбор — подождать дольше.

Приоритет обдуманного и терпеливого процесса охлаждения является отличительной чертой безопасной и эффективной работы печи.

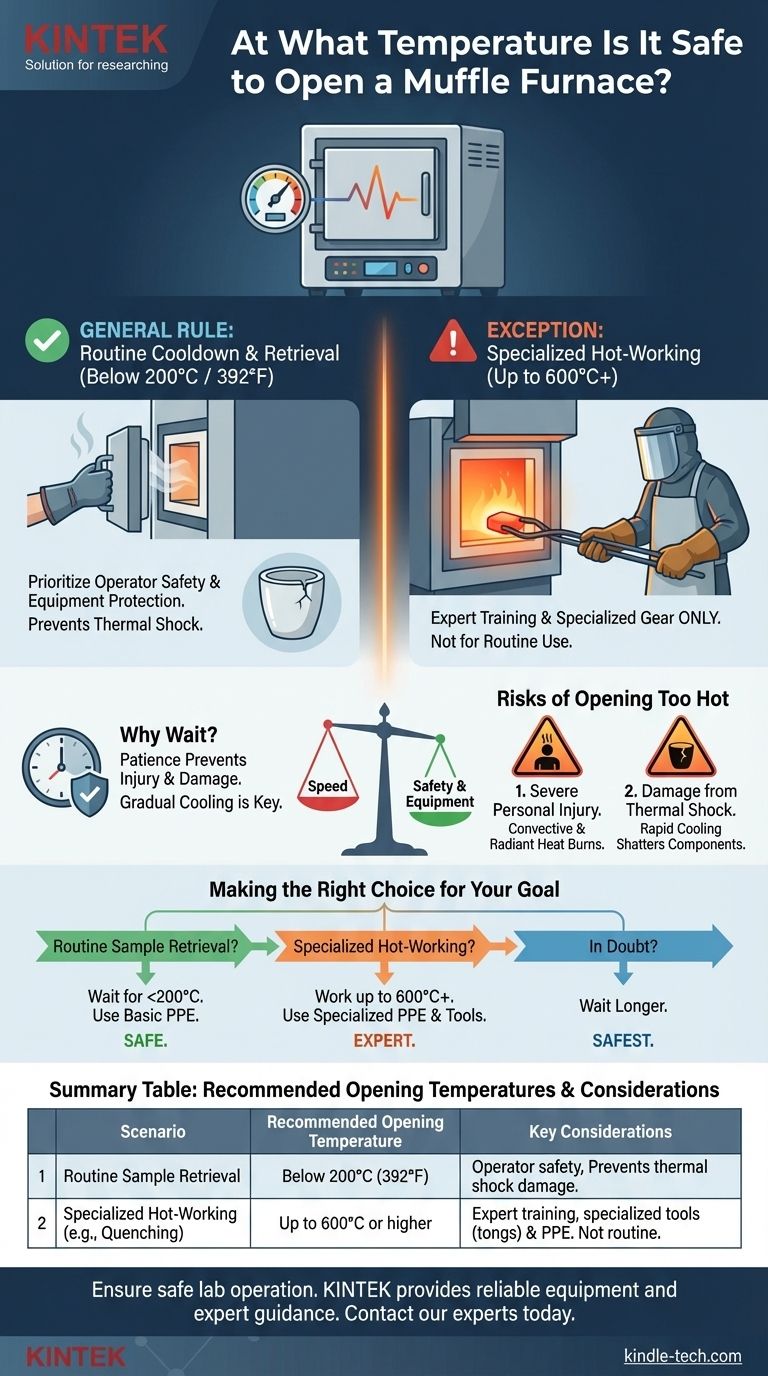

Сводная таблица:

| Сценарий | Рекомендуемая температура открытия | Ключевые соображения |

|---|---|---|

| Рутинное извлечение образцов | Ниже 200°C (392°F) | Приоритет безопасности оператора и предотвращение повреждения оборудования от термического шока. |

| Специализированная горячая обработка (например, закалка) | До 600°C или выше | Требует экспертной подготовки, специализированных инструментов (длинные щипцы) и обширных СИЗ. Не для рутинного использования. |

Обеспечьте безопасную и эффективную работу вашей лаборатории. Спешка с открытием муфельной печи может привести к серьезным травмам персонала и дорогостоящему повреждению чувствительных компонентов. В KINTEK мы специализируемся на предоставлении надежного лабораторного оборудования и расходных материалов, а также экспертного руководства, необходимого для безопасной эксплуатации. Защитите свою команду и свои инвестиции — свяжитесь с нашими экспертами сегодня, чтобы найти подходящую печь и аксессуары для безопасности, соответствующие конкретным потребностям вашей лаборатории.

Визуальное руководство

Связанные товары

- Лабораторная муфельная печь с нижним подъемом

- Муфельная печь 1700℃ для лаборатории

- Муфельная печь 1800℃ для лаборатории

- Муфельная печь 1400℃ для лаборатории

- Лабораторная трубчатая печь высокой температуры 1400℃ с корундовой трубкой

Люди также спрашивают

- Как работает высокотемпературная муфельная печь при подготовке керамических листов твердого электролита LATP?

- Какова цель предварительной обработки смесей прекурсоров при 700°C? Обеспечение синтеза чистой шпинельной фазы

- Каково применение муфельной печи в анализе пищевых продуктов? Освойте прокаливание для точного определения содержания минералов

- Почему для прокаливания силикалита-1 со скоростью 0,2°C/мин требуется программируемая высокотемпературная печь?

- Как муфельная печь обеспечивает надежность при кальцинационной обжиге? Достижение точности при конверсии гранул

- Что такое метод озоления? Руководство по точному анализу минерального состава

- Какая проблема решается высокотемпературным плавлением в солях или пероксиде натрия? Преодоление стабильности кристаллической решетки катализатора

- Какую роль играет программируемая камерная печь сопротивления в контроле микроструктуры Al0.6CoCrFeNi/5052Al?