Оглавление

- Введение в рентгенофлуоресцентный анализ и подготовку образцов

- П - подготовка: Обеспечение однородности образцов

- R - Разработка рецептов: Ключевые факторы для успешного прессования гранул

- E - Оборудование: Выбор правильных инструментов для работы

- S - Безопасность: Защита себя во время пробоподготовки

- S - Стратегия: Разработка последовательного рабочего процесса подготовки

- T - Обучение и соблюдение требований: Повышение квалификации в области рентгенографии

- Заключение: Достижение совершенства в рентгенофлуоресцентном анализе

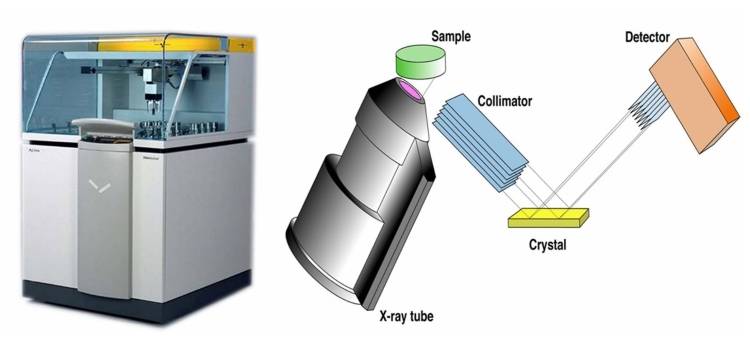

Введение в рентгенофлуоресцентный анализ и подготовку образцов

Рентгенофлуоресцентный анализ (РФА) - важнейший метод определения характеристик материалов, позволяющий получать неразрушающие и высокоточные результаты. Однако качество этих результатов в значительной степени зависит от тщательности подготовки образцов. Эта статья посвящена тонкостям подготовки образцов для рентгенофлуоресцентного анализа, подчеркивая важность обеспечения однородности, разработки эффективных рецептов, выбора подходящего оборудования, соблюдения протоколов безопасности, разработки последовательных рабочих процессов, а также повышения квалификации путем обучения и соблюдения требований. Освоив эти 7 проверенных стратегий PRESS, вы сможете добиться оптимальных результатов и поднять свой рентгенофлуоресцентный анализ на новую высоту точности и надежности.

P - Подготовка: Обеспечение однородности образцов

Подготовка образцов к рентгенофлуоресцентному анализу (РФА) - важнейший этап, который напрямую влияет на точность и надежность результатов. Цель состоит в том, чтобы создать однородный образец, который можно последовательно проанализировать, независимо от типа или формы материала. В этом разделе мы подробно рассмотрим шаги по подготовке образцов к рентгенофлуоресцентному анализу, уделяя особое внимание методам гомогенизации и использованию высококачественных матриц для рентгенофлуоресцентных гранул.

Методы гомогенизации

Гомогенизация - это процесс придания образцу однородного состава, что необходимо для проведения точного рентгенофлуоресцентного анализа. Для получения однородного образца обычно используются следующие методы:

-

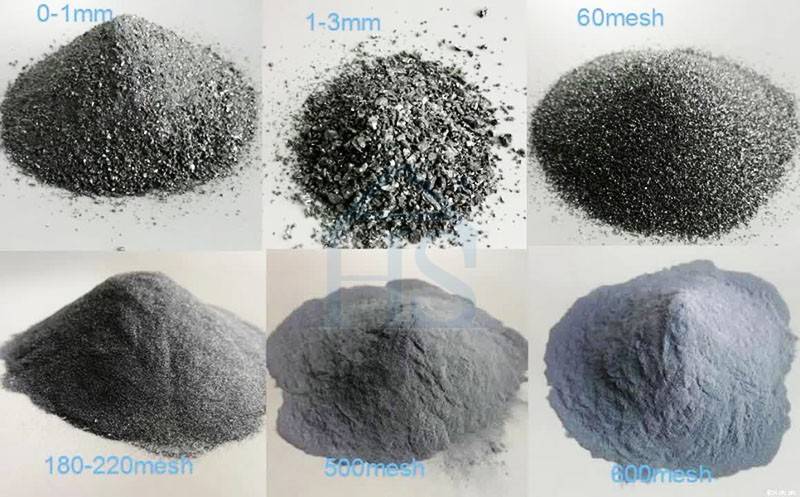

Измельчение: Первым шагом в гомогенизации является измельчение образца до состояния тонкого порошка. В идеале размер зерен должен быть менее 75 микрометров (<75 мкм). Это обеспечивает равномерное распределение образца и снижает вероятность образования пустот, которые могут привести к неточным показаниям. Для большинства материалов достаточно измельчения до такой степени тонкости, чтобы получить однородный образец.

-

Смешивание: После измельчения образец необходимо тщательно перемешать. Это можно сделать с помощью механического миксера или вручную перемешивая порошок. Цель состоит в том, чтобы все части образца были представлены в равной степени, что очень важно для последовательного рентгенофлуоресцентного анализа.

-

Связывание: В некоторых случаях в порошкообразный образец добавляют связующее вещество. Это особенно полезно для образцов, которые трудно спрессовать в гранулы. К распространенным связующим веществам относятся смеси целлюлозного воска, которые обычно добавляются в пропорции 20-30 % связующего вещества к образцу. Связующее вещество помогает удерживать образец вместе и обеспечивает однородность гранул.

Использование высококачественных матриц для рентгеновских гранул

После того как образец гомогенизирован, следующим шагом является прессование его в гранулы с помощью высококачественных пресс-форм для рентгенофлуоресцентных гранул. Прессованные гранулы - это более строгий метод подготовки проб по сравнению с сыпучими порошками, поскольку они обеспечивают более однородную и стабильную поверхность для анализа. Ниже приведены шаги, которые необходимо выполнить:

-

Загрузка фильеры: Убедитесь, что образец не содержит комков и является полностью однородным, прежде чем загружать его в фильеру. Это очень важно для создания однородной гранулы.

-

Прессование: Используйте гидравлический пресс для создания давления на образец. Рекомендуемый диапазон давления составляет от 20 до 30 тонн (20-30T). Этого давления достаточно для создания плотной, однородной гранулы, не вызывая перегрева или деформации образца.

-

Смазка: Нанесите смазку для прессования гранул на матрицу, чтобы предотвратить прилипание образца. Это гарантирует, что гранулу можно будет легко извлечь из матрицы, не повредив ее.

-

Повторите: Повторите процесс для каждого образца, который необходимо спрессовать в гранулу XRF. Последовательность в процессе прессования - залог получения надежных результатов.

Советы по успешному прессованию рентгенофлуоресцентных гранул

-

Качественные штампы: Всегда используйте высококачественные пресс-формы для прессования гранул XRF, чтобы обеспечить стабильные формы и размеры гранул. Некачественные штампы могут привести к образованию неровных гранул, что может повлиять на точность анализа.

-

Средства индивидуальной защиты (СИЗ): При работе с порошкообразными образцами всегда надевайте соответствующие СИЗ, такие как перчатки и защитные очки. Это защитит вас от потенциальных опасностей, связанных с работой с мелкими порошками.

-

Инструкции производителя: Следуйте инструкциям производителя гидравлического пресса, чтобы убедиться, что вы используете его правильно. Это включает в себя установку соответствующего давления и обеспечение правильного функционирования пресса.

-

Стандарты калибровки: Выбранный вами метод подготовки образцов должен применяться к калибровочным стандартам, а также к любым неизвестным образцам. Это гарантирует точность и последовательность калибровки.

R - разработка рецепта: Ключевые факторы для успешного прессования гранул

Разработка рецепта пробоподготовки для прессования гранул - важнейший шаг в обеспечении точных и воспроизводимых результатов анализа. Этот процесс включает в себя несколько ключевых факторов, которые необходимо тщательно контролировать. К ним относятся размер частиц, выбор связующего вещества, коэффициент разбавления образца, давление прессования и толщина гранул. Каждый из этих элементов играет решающую роль в качестве и консистенции конечного гранулята, что напрямую влияет на достоверность аналитических данных.

Размер частиц

Размер частиц образца является одним из наиболее важных факторов при подготовке гранул. Меньший размер частиц обычно приводит к лучшему связыванию и более однородным гранулам. В идеале образцы должны быть измельчены до размера частиц менее 50 мкм. Однако частицы размером до 75 мкм могут дать приемлемые результаты. Причина использования мелких частиц заключается в том, что они обеспечивают большую площадь поверхности для прилипания связующего вещества, в результате чего гранулы получаются более прочными и сплоченными. Более крупные частицы, напротив, могут привести к образованию слабых гранул, которые могут сломаться во время работы или анализа, повредив спектрометр и испортив образец.

Выбор связующего вещества

Выбор связующего вещества - еще один важнейший элемент процесса подготовки гранул. Связующее вещество удерживает частицы образца вместе под давлением, обеспечивая целостность гранул во время анализа. Чаще всего для прессования гранул используются органические материалы, такие как воск, целлюлоза или поливиниловый спирт (ПВА). Выбор связующего зависит от типа образца и используемой аналитической методики. Например, для рентгенофлуоресцентного анализа (РФА) часто предпочитают восковые связующие благодаря их способности выдерживать высокое давление и обеспечивать хорошую целостность гранул.

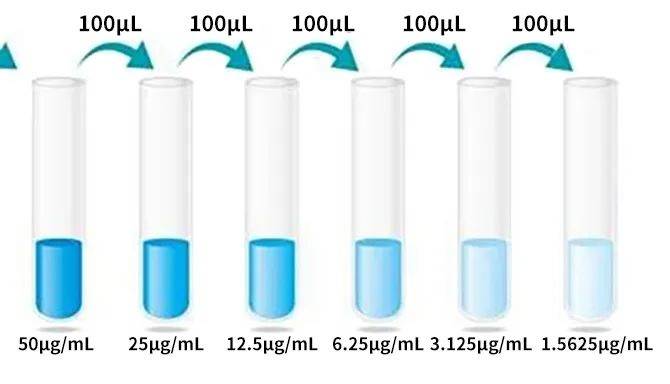

Коэффициент разбавления пробы

Коэффициент разбавления пробы, который означает соотношение связующего и пробы, также является критическим параметром. Обычно соотношение связующего к образцу составляет 20-30 %. Такое соотношение обеспечивает достаточное связывание образца без чрезмерного разбавления. Чрезмерное разбавление может привести к образованию слабых гранул, склонных к разрушению, а недостаточное разбавление может привести к образованию слишком плотных гранул, с которыми трудно работать. Последовательность в соотношении связующего к образцу очень важна для воспроизводимости, поскольку любое отклонение может внести погрешности в результаты анализа.

Давление прессования

Давление прессования - это сила, прикладываемая к смеси образца и связующего для формирования гранул. Необходимое давление может варьироваться в зависимости от типа образца и используемого связующего. Как правило, при более высоком давлении получаются более плотные и прочные гранулы. Однако чрезмерное давление может привести к растрескиванию или деформации гранул, что приведет к несовместимым результатам. При разработке метода важно установить оптимальный диапазон давления для каждого типа образца. Этот диапазон должен поддерживаться постоянно, чтобы обеспечить качество и воспроизводимость гранул.

Толщина гранул

Толщина конечной гранулы - еще один фактор, который необходимо тщательно контролировать. Толщина гранул влияет на однородность образца и точность результатов анализа. Более толстые гранулы могут привести к неравномерному сжатию, что приведет к изменению аналитического сигнала. И наоборот, слишком тонкие гранулы могут быть слишком хрупкими и склонными к разрушению. Идеальная толщина гранул обычно составляет 1-3 мм, в зависимости от конкретных требований используемого аналитического метода. Поддержание постоянной толщины гранул имеет решающее значение для обеспечения воспроизводимости результатов.

Практические соображения

На практике подготовка прессованных гранул включает несколько этапов, в том числе измельчение образца до соответствующего размера частиц, смешивание образца со связующим веществом, перенос смеси в пресс-форму для прессования гранул и приложение необходимого давления для формирования гранул. Каждый этап должен быть выполнен с точностью и последовательностью, чтобы обеспечить качество конечного гранулята. Внимание к деталям, таким как равномерное распределение смеси образцов в фильере и правильное давление, необходимо для минимизации ошибок и получения надежных аналитических результатов.

E - Оборудование: Выбор правильных инструментов для работы

Когда речь идет о прессовании гранул для XRF, выбор правильного оборудования имеет решающее значение для обеспечения точных и стабильных результатов. Этот процесс включает в себя создание однородных твердых гранул из порошкообразных образцов, которые затем анализируются с помощью рентгенофлуоресцентной (XRF) спектроскопии. В этом разделе мы расскажем вам о ключевых моментах при выборе лучшего оборудования, уделяя особое внимание преимуществам использования автоматических гидравлических прессов KINTEK и других необходимых инструментов.

Ручные и автоматические гидравлические прессы

Выбор между ручным и автоматическим гидравлическим прессом во многом зависит от объема и частоты проведения XRF-анализа. Ручные гидравлические прессы, хотя и являются экономически эффективными, требуют значительных физических усилий от оператора, особенно при применении высокого давления. Как правило, такие прессы обеспечивают максимальное усилие давления до 250 кН, имеют наглядные индикаторы усилия давления и простое управление с помощью ручного рычага. Однако усилия, необходимые для достижения высокого давления, могут быть напряженными и приводить к несоответствиям в приложении давления.

С другой стороны, автоматические гидравлические прессы имеют ряд преимуществ, особенно в загруженных лабораториях. Эти прессы могут быть запрограммированы на автономную работу после настройки, что позволяет техническому персоналу сосредоточиться на других задачах. Автоматические прессы выпускаются в различных конфигурациях, например 30, 40 и 60 тонн, и требуют значительно меньше усилий при эксплуатации. Это делает их идеальными для частых прессовых работ, так как они обеспечивают большую точность и последовательность благодаря устранению переменных факторов во время использования.

Преимущества автоматических гидравлических прессов KINTEK

Компания KINTEK является известным производителем высококачественного лабораторного оборудования, в том числе автоматических гидравлических прессов, специально разработанных для подготовки гранул XRF. Эти прессы разработаны с учетом требований лабораторий с высокой пропускной способностью и обладают рядом ключевых преимуществ:

-

Высокая производительность: Автоматические гидравлические прессы KINTEK разработаны для быстрой и эффективной работы, позволяя быстро подготовить несколько образцов. Это особенно полезно в лабораториях, где проводится большой объем XRF-анализов.

-

Интегрированные фильеры для гранул: Эти прессы оснащены встроенными матрицами для гранул, которые упрощают процесс и сокращают время, необходимое для подготовки каждого образца. Штампы предназначены для обеспечения равномерного формирования гранул, что очень важно для точного XRF-анализа.

-

Автоматизация: Автоматизация прессов KINTEK позволяет получать стабильные и повторяющиеся результаты. После программирования пресс может работать автономно, снижая риск человеческой ошибки и гарантируя, что каждый образец будет подготовлен по одним и тем же строгим стандартам.

-

Простота использования: Прессы KINTEK имеют дружественный интерфейс, что делает их простыми в эксплуатации даже для людей с ограниченными техническими знаниями. Прессы также оснащены автоматическими системами сброса давления для предотвращения перенапряжения и обеспечения безопасности.

-

Универсальность: Автоматические гидравлические прессы KINTEK совместимы с различными типами образцов, включая те, которые могут потребовать дополнительных связующих веществ, таких как воск. Такая универсальность гарантирует, что пресс может работать с широким спектром материалов, что делает его универсальным инструментом в любой XRF-лаборатории.

Необходимые инструменты для подготовки гранул для рентгенофлуоресцентного анализа

В дополнение кгидравлического прессадля успешной подготовки гранул XRF необходимы еще несколько инструментов:

-

XRF-гранулы: Эти фильеры специально разработаны для создания однородных гранул из порошкообразных образцов. Они бывают разных диаметров, например 40 мм, 32 мм и 15 мм, что позволяет гибко подбирать размер образца.

-

Смазка для прессования гранул: Нанесение тонкого слоя смазки на матрицу и образец может предотвратить прилипание и обеспечить плавное формирование гранул. Смазки выпускаются в различных составах для разных типов образцов.

-

Порошкообразный образец: Качество порошкообразного образца имеет решающее значение для точного рентгенофлуоресцентного анализа. Образцы должны быть измельчены в мелкий однородный порошок без комков и примесей.

-

Восковые связующие: В некоторых случаях, особенно при работе с материалами, которые плохо связываются или легко распадаются, добавление воскового связующего на стадии измельчения может улучшить формирование гранул. Восковые связующие вещества выпускаются в виде порошка или таблеток и должны использоваться в минимальном количестве, необходимом для надежного связывания образца.

S - Безопасность: Защита себя во время подготовки образцов

При работе с порошкообразными образцами и использовании оборудования для рентгеновской флуоресценции (XRF) безопасность должна стоять на первом месте. Важность средств индивидуальной защиты (СИЗ) и соблюдения протоколов безопасности невозможно переоценить. В этом разделе рассматриваются важнейшие аспекты безопасности, обеспечивающие благополучие операторов и точность измерений.

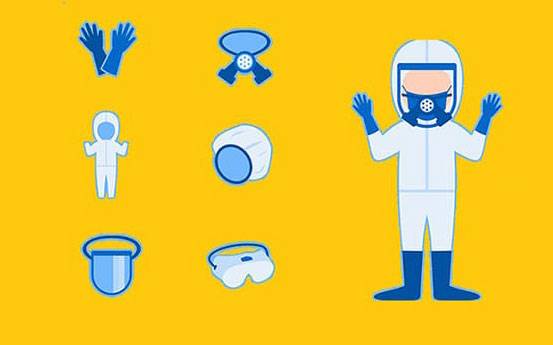

Средства индивидуальной защиты (СИЗ)

Средства индивидуальной защиты необходимы для защиты операторов от потенциальных опасностей, связанных с порошкообразными образцами и оборудованием XRF. Основные компоненты СИЗ включают:

- Перчатки: Всегда надевайте перчатки при работе с порошкообразными образцами, чтобы предотвратить контакт кожи с потенциально опасными материалами. Обычно рекомендуются одноразовые нитриловые перчатки благодаря их устойчивости к химическим веществам и порошкам.

- Защитные очки или очки-тренажеры: Защитите глаза от взвешенных в воздухе частиц и возможных брызг. Защитные очки с боковыми щитками обеспечивают комплексную защиту.

- Лабораторные халаты или фартуки: Носите лабораторный халат или фартук, чтобы защитить одежду от загрязнения. Убедитесь, что халат изготовлен из легко очищаемого материала или является одноразовым.

- Защита органов дыхания: В зависимости от характера порошка может потребоваться респиратор, чтобы предотвратить вдыхание вредных частиц. Используйте респиратор, одобренный регулирующими органами, такими как NIOSH.

Протоколы безопасности при работе с порошкообразными образцами

Правильное обращение с порошкообразными образцами имеет решающее значение для предотвращения загрязнения и обеспечения точности измерений. Вот несколько основных протоколов, которым необходимо следовать:

- Чистота поверхности: Если есть сомнения в чистоте поверхности образца, сравните результаты измерений до и после измельчения. Если результаты значительно отличаются, измельчите образец еще раз, пока разница между результатами до и после измельчения не окажется в пределах погрешности измерений.

- Подготовка образца: Существует несколько методов подготовки образцов порошка, таких как уплотнение порошка, сплавление с флюсом или прямое измерение тонкоизмельченного порошка. Самый простой и распространенный метод - прямое измерение тонкоизмельченного порошка. В этом случае необходимо подготовить кюветы и пленку для измерений. Проконсультируйтесь с поставщиком, чтобы выбрать наиболее подходящий тип пленки для конкретной задачи и устройства.

- Однородность образца: Сыпучие образцы, такие как автомобильные катализаторы или почва, должны быть тщательно измельчены перед измерением. Крупные частицы могут сильно отличаться по составу, поэтому измельчение обеспечивает получение более однородного образца. Если измельчение невозможно, усредните результаты нескольких измерений, перемешав образец в кювете.

Правила безопасности при работе с рентгенофлуоресцентным оборудованием

В рентгенофлуоресцентном оборудовании используется рентгеновское излучение, которое может быть вредным для здоровья при неправильном обращении. Вот некоторые правила безопасности, которые следует соблюдать при работе с рентгенофлуоресцентными анализаторами:

-

Радиационная безопасность: XRF-анализаторы излучают рентгеновские лучи, которые могут быть вредны при неправильном обращении. Всегда соблюдайте правила радиационной безопасности:

- Держитесь подальше от других людей.: При использовании XRF-анализатора держитесь на расстоянии не менее 15 футов (4,57 м) от других людей.

- Используйте принадлежности: Используйте дополнительные принадлежности, такие как испытательные стенды, чтобы минимизировать прямое воздействие рентгеновского луча.

- Обучение: Проводите обучение операторов по радиационной безопасности, чтобы убедиться, что они понимают риски и способы их уменьшения.

- Избегайте прямого облучения: Никогда не держите образец во время анализа. Следите за индикатором основного луча и убедитесь, что луч не направлен ни на кого.

- Осторожное обращение с образцом: Обращайтесь с рентгенофлуоресцентным оборудованием и используйте его с осторожностью. Храните его в соответствии с местными требованиями к хранению.

-

Защитные картриджи: Защитный картридж необходим для защиты детектора от пыли и загрязнений. Регулярно заменяйте картридж, так как грязь и частицы из ранее измеренных образцов могут накапливаться и искажать результаты измерений. Частота замены может зависеть от типа измеряемого образца. Например, алюминиевые сплавы могут оставлять частицы, которые влияют на точность последующих измерений, что требует более частой замены картриджа.

-

Время измерения: Обеспечьте достаточное время измерения для получения точных результатов. Время измерения влияет на точность измерения; более длительное время приводит к меньшим ошибкам при определении концентрации элементов в образце. Обычно для получения точного количественного результата требуется 10-30 секунд.

S - Стратегия: Разработка согласованного рабочего процесса подготовки

Создание стандартизированного рабочего процесса подготовки проб для рентгенофлуоресцентного анализа имеет решающее значение для обеспечения последовательности и воспроизводимости результатов. Правильная пробоподготовка - основа точного рентгенофлуоресцентного анализа (РФА), поскольку она существенно влияет на качество аналитических данных. В отличие от других аналитических методов, рентгенофлуоресцентный анализ не требует тщательной пробоподготовки, что делает его экономически выгодным и эффективным методом. Однако это не умаляет важности создания надежного протокола подготовки.

Твердые образцы

Твердые образцы, начиная от неподготовленных металлических кусков и заканчивая разрезанными и отполированными образцами металла, требуют тщательной обработки для получения точных результатов. Идеальный образец для рентгенофлуоресцентного анализа должен иметь идеально ровную поверхность. Неровные поверхности могут изменить расстояние между образцом и источником рентгеновского излучения, что приведет к ошибкам в измерениях. Все рентгенофлуоресцентные системы калибруются на основе фиксированного расстояния между образцом и источником, поэтому любое отклонение может повлиять на интенсивность рентгеновских сигналов.

Для металлических сплавов и других твердых образцов минимальной подготовки может быть достаточно для качественного анализа. Однако для получения более количественных результатов рекомендуется разрезать и отполировать образцы. Обработка поверхности особенно важна для легких элементов, так как шероховатые поверхности могут вызывать рассеяние и повторное поглощение длинноволновых элементов. Этот эффект зависит от энергии, то есть если на более тяжелые элементы, такие как никель (Ni), он может не оказывать существенного влияния, то более легкие элементы, такие как углерод (C) или сера (S), могут продемонстрировать резкое снижение интенсивности сигнала. Поэтому для точного анализа необходима более тонкая обработка поверхности, достигаемая с помощью токарной обработки или шлифования.

Порошковые образцы

Подготовка порошковых образцов для рентгенофлуоресцентного анализа включает несколько методов, в том числе уплотнение порошка, сплавление с флюсом и прямое измерение тонкоизмельченного порошка. Самый простой и распространенный метод - прямое измерение тонкоизмельченного порошка. Этот процесс включает в себя выбор подходящих кювет и пленок для измерений. Существуют различные типы пленок для XRF, и выбор подходящей зависит от конкретной задачи и используемого прибора. Консультация с поставщиком имеет решающее значение для выбора наиболее подходящей пленки.

Последовательность рабочего процесса

Для поддержания последовательности в проведении рентгенофлуоресцентного анализа необходимо установить стандартный рабочий процесс. Это включает в себя:

-

Чистота поверхности: Перед анализом убедитесь, что поверхность образца чистая. Если есть сомнения в чистоте поверхности, сравните результаты измерений до и после шлифовки образца. Если результаты значительно отличаются, отшлифуйте образец еще раз, пока разница между результатами до и после шлифовки не окажется в пределах погрешности измерения.

-

Тонкая настройка и калибровка: Регулярно проверяйте, не требуется ли тонкая настройка или калибровка вашего рентгенофлуоресцентного оборудования. Это гарантирует, что прибор работает оптимально и дает точные результаты.

-

Оптимизация времени тестирования: Регулируйте время тестирования для интересующих вас элементов, чтобы получить достаточное количество данных без излишнего затягивания анализа.

-

Выбор правильного режима: Выберите подходящий режим в рентгенофлуоресцентном анализаторе в зависимости от типа образца и анализируемых элементов. Это может существенно повлиять на точность результатов.

-

Понимание характеристик образца: Помните о влиянии неоднородности, влажности, размера частиц и различных контейнеров для образцов на результаты. Эти факторы могут внести вариабельность и должны контролироваться для обеспечения воспроизводимости.

-

Разработка стандартных операционных процедур (СОП): Установите "подходящий для цели" метод и разработайте СОПы для подготовки проб. Это гарантирует, что все операторы будут следовать одному и тому же протоколу, что приведет к получению стабильных результатов.

-

Контроль и обеспечение качества (QC/QA): Применяйте соответствующие меры по контролю и обеспечению качества, включая использование сертифицированных стандартных образцов (CRM), холостых проб, дубликатов и реплик, соответствующих матрице. Это поможет проверить точность и надежность результатов.

T - Обучение и соответствие: Повышение квалификации в области РФА

Роль обучения и соблюдения требований в освоении рентгенофлуоресцентного анализа трудно переоценить. Правильное обучение обеспечивает понимание операторами тонкостей технологии рентгеновской флуоресценции (XRF), а соблюдение местных норм гарантирует безопасное и точное использование оборудования. В этом разделе мы рассмотрим важность обучения, необходимость соблюдения местных норм и преимущества подготовки квалифицированного персонала.

Важность обучения

Обучение является краеугольным камнем профессионального рентгенофлуоресцентного анализа. Операторы должны быть хорошо знакомы с теоретическими аспектами технологии XRF, включая ее принципы, работу и возможные подводные камни. Без соответствующей подготовки даже самые современные рентгенофлуоресцентные анализаторы могут давать неточные результаты из-за неправильной калибровки, пробоподготовки или методов измерения.

Например, одна из самых распространенных ошибок новичков - неправильная пробоподготовка. Твердые образцы, такие как металлы и сплавы, должны быть тщательно очищены, причем для разных материалов часто требуются разные файлы, чтобы предотвратить перекрестное загрязнение. Сыпучие образцы, такие как почва или автомобильные катализаторы, необходимо измельчить или смешать для обеспечения однородности. Правильное обучение гарантирует, что операторы понимают все эти нюансы, что приводит к получению более надежных и точных результатов.

Еще один важный аспект - калибровка. В рентгенофлуоресцентных анализаторах используется метод фундаментальных параметров, который требует предварительной калибровки под конкретные задачи. Неправильное использование анализатора, откалиброванного для сплавов, для анализа драгоценных металлов или почвы может привести к снижению точности. Обучение дает операторам знания, позволяющие выбрать правильную калибровку для каждой задачи, обеспечивая количественные, а не только качественные результаты.

Соответствие местным нормам

Не менее важно соблюдение местных норм. В рентгенофлуоресцентных анализаторах используется рентгеновское излучение, которое, несмотря на низкую интенсивность, может представлять опасность для здоровья при длительном воздействии. В разных странах и штатах действуют свои правила, которые охватывают такие аспекты, как допустимые пределы воздействия, протоколы безопасности и стандарты оборудования. Соблюдение этих норм обеспечивает не только безопасность операторов, но и надежность получаемых данных.

Например, некоторые нормы могут требовать от операторов ношения защитного снаряжения или ограничения продолжительности непрерывного воздействия. Другие могут предписывать регулярные проверки и обслуживание оборудования. Понимание и соблюдение этих норм имеет решающее значение для поддержания безопасной рабочей среды и обеспечения работы рентгенофлуоресцентного анализатора в рамках установленных законом параметров.

Заключение: Достижение совершенства в рентгенофлуоресцентном анализе

Овладение навыками подготовки проб для рентгенофлуоресцентного анализа - важнейший шаг на пути к получению точных и надежных результатов анализа. Реализация 7 стратегий PRESS - подготовка, разработка рецептуры, выбор оборудования, протоколы безопасности, разработка стратегии, обучение и соблюдение требований - позволит вам значительно повысить качество и стабильность результатов рентгенофлуоресцентного анализа. Эти стратегии не только обеспечивают оптимальную подготовку проб, но и защищают аналитика и поддерживают соответствие отраслевым стандартам. Благодаря глубокому пониманию и применению этих методов вы сможете достичь совершенства в рентгенофлуоресцентном анализе, что приведет к более точным и надежным результатам в ваших исследованиях и процессах тестирования.

Связанные товары

- Лабораторная пресс-форма для таблетирования порошка в пластиковом кольце XRF & KBR для ИК-Фурье

- Автоматический лабораторный гидравлический пресс для таблеток XRF и KBR

- Лабораторная пресс-форма для таблетирования порошка в стальном кольце XRF & KBR для ИК-Фурье

- Лабораторная пресс-форма для таблеток из борной кислоты для рентгенофлуоресцентного анализа

- Лабораторный гидравлический пресс для таблеток для применений XRF KBR FTIR

Связанные статьи

- Эксплуатация автоматического лабораторного пресса для гранулирования XRF

- Советы и рекомендации по таблетированию твердых образцов с помощью РФА

- Прессование образцов порошков и формование полимерных пленок: подробное руководство

- Руководство для Xrf Pellet Press

- Определение оптимального давления для прессования гранул XRF